Catalysts

29 Jul 2025

Clariant Catalysts and Shanghai Electric launch alliance to advance China’s energy transition

Clariant, a sustainability-focused specialty chemical company, today announced that it has signed a strategic cooperation agreement with Shanghai Boiler Works, a full subsidiary of Shanghai Electric, specializing in energy conversion and the development of new energy applications, to jointly foster innovation in sustainable energy solutions. The partners will combine their expertise to advance green energy projects in China. The agreement is the result of close and successful cooperation in Shanghai Electric’s new biomass-to-green methanol plant in Taonan, Jilin Province, China. In addition to supplying its MegaMax catalysts, Clariant provided technical on-site support during the successful startup of the 50,000 tons/y plant. The second phase of the project, with a capacity of 200,000 tons/y green methanol and 10,000 tons/y SAF, is expected to start production in 2027. The ceremony for the official signing of the partnership contract took place last week at the Clariant Innovation Center in Frankfurt, Germany.

Clariant, a sustainability-focused specialty chemical company, today announced that it has signed a strategic cooperation agreement with Shanghai Boiler Works, a full subsidiary of Shanghai Electric, specializing in energy conversion and the development of new energy applications, to jointly foster innovation in sustainable energy solutions. The partners will combine their expertise to advance green energy projects in China. The agreement is the result of close and successful cooperation in Shanghai Electric’s new biomass-to-green methanol plant in Taonan, Jilin Province, China. In addition to supplying its MegaMax catalysts, Clariant provided technical on-site support during the successful startup of the 50,000 tons/y plant. The second phase of the project, with a capacity of 200,000 tons/y green methanol and 10,000 tons/y SAF, is expected to start production in 2027. The ceremony for the official signing of the partnership contract took place last week at the Clariant Innovation Center in Frankfurt, Germany.

3 Jun 2025

Clariant's ShiftMax™ 100 RE catalyst powers INERATEC´s groundbreaking e-Fuels plant

Clariant, a sustainability-focused specialty chemical company, today announced that its ShiftMax 100 RE catalyst is powering INERATEC's advanced e-Fuels production plant, “ERA ONE” in the industrial park Frankfurt Hoechst, Germany. The facility, officially opening on June 3, will recycle approximately 8,000 tons of CO₂ annually and transform it into up to 2,500 tons of synthetic fuels and waxes. This production capacity represents one of the largest Power-to-Liquids operations globally, positioning both companies at the forefront of sustainable fuel technology innovation.

Clariant, a sustainability-focused specialty chemical company, today announced that its ShiftMax 100 RE catalyst is powering INERATEC's advanced e-Fuels production plant, “ERA ONE” in the industrial park Frankfurt Hoechst, Germany. The facility, officially opening on June 3, will recycle approximately 8,000 tons of CO₂ annually and transform it into up to 2,500 tons of synthetic fuels and waxes. This production capacity represents one of the largest Power-to-Liquids operations globally, positioning both companies at the forefront of sustainable fuel technology innovation.

30 Apr 2025

Beyond technical service: How Clariant's Applied Catalyst Technology (ACT) team transforms technical support

Lorena Oviol, Head of Applied Catalyst Technology at Clariant Catalysts, unveils how to achieve real impact by maximizing plant performance with catalysts. Her revelations about the fusion of human expertise and cutting-edge technology will prove invaluable for anyone seeking to understand how catalyst optimization offers a competitive advantage.

Lorena Oviol, Head of Applied Catalyst Technology at Clariant Catalysts, unveils how to achieve real impact by maximizing plant performance with catalysts. Her revelations about the fusion of human expertise and cutting-edge technology will prove invaluable for anyone seeking to understand how catalyst optimization offers a competitive advantage.

22 Apr 2025

Clariant & Midrex fortify partnership in DRI, helping to decarbonize the steel industry

Clariant, a sustainability-focused specialty chemical company, today announced that it has renewed its successful cooperation with Midrex and will intensify collaboration in direct reduced iron (DRI) technology for steel production. A low-carbon alternative to conventional coal-based ironmaking, natural gas-based DRI converts natural gas with recycled CO2 and H2O to generate reducing gas for the production process. The technology combines MIDREX® Reformers with Clariant-manufactured REFORMEX® Catalysts, which offer superior activity and stability to increase productivity, reduce energy consumption, and minimize carbon emissions. MIDREX DRI technology avoids around one ton of CO2 per ton of crude steel.

Clariant, a sustainability-focused specialty chemical company, today announced that it has renewed its successful cooperation with Midrex and will intensify collaboration in direct reduced iron (DRI) technology for steel production. A low-carbon alternative to conventional coal-based ironmaking, natural gas-based DRI converts natural gas with recycled CO2 and H2O to generate reducing gas for the production process. The technology combines MIDREX® Reformers with Clariant-manufactured REFORMEX® Catalysts, which offer superior activity and stability to increase productivity, reduce energy consumption, and minimize carbon emissions. MIDREX DRI technology avoids around one ton of CO2 per ton of crude steel.

9 Apr 2025

Clariant teams with Technip Energies to introduce new catalyst for unprecedented low steam-to-oil ratios in styrene production

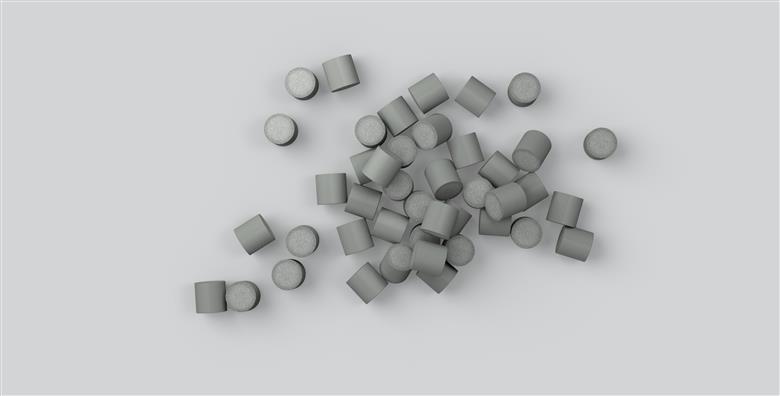

Clariant, a global leader in specialty chemicals, today announced the launch of StyroMax UL-100, its most advanced ethylbenzene dehydrogenation catalyst to date. This innovative catalyst achieves exceptional performance at unprecedented low steam-to-oil ratios (S/O) of 0.76 by weight, setting a new industry benchmark in SM production efficiency.

Clariant, a global leader in specialty chemicals, today announced the launch of StyroMax UL-100, its most advanced ethylbenzene dehydrogenation catalyst to date. This innovative catalyst achieves exceptional performance at unprecedented low steam-to-oil ratios (S/O) of 0.76 by weight, setting a new industry benchmark in SM production efficiency.

3 Apr 2025

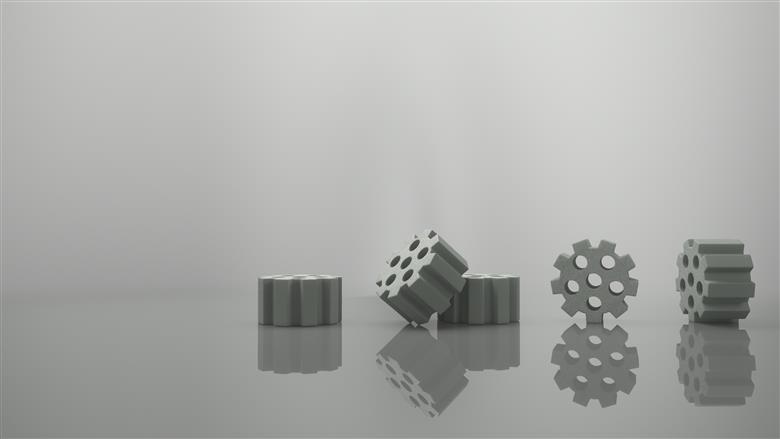

Clariant’s MegaMax™ 900 catalyst: Powerful start at European Energy’s e-methanol plant

Clariant, a sustainability-focused specialty chemical company, today announced the successful startup of its MegaMax 900 methanol synthesis catalyst at European Energy’s e-methanol plant. Located in Kasso, Denmark, the facility is one of the world’s first and, up to now, largest commercial e-methanol plant, using biogenic CO2 and green hydrogen to produce up to 42,000 tons of green methanol annually. Clariant's Applied Catalyst Technology (ACT) technical service team provided on-site support throughout the startup procedure, overseeing the catalyst loading, reduction, and startup. MegaMax 900 is operating with excellent activity and stability despite the challenging conditions of CO2-to-methanol conversion.

Clariant, a sustainability-focused specialty chemical company, today announced the successful startup of its MegaMax 900 methanol synthesis catalyst at European Energy’s e-methanol plant. Located in Kasso, Denmark, the facility is one of the world’s first and, up to now, largest commercial e-methanol plant, using biogenic CO2 and green hydrogen to produce up to 42,000 tons of green methanol annually. Clariant's Applied Catalyst Technology (ACT) technical service team provided on-site support throughout the startup procedure, overseeing the catalyst loading, reduction, and startup. MegaMax 900 is operating with excellent activity and stability despite the challenging conditions of CO2-to-methanol conversion.

Industries

The companies featured on PressReleaseFinder are active in several industries. If you are interested in a specific industry, please select one to filter the available press releases.

Additives Adhesives Agriculture Architecture Automation Automotive Aviation Beverage Biotechnology Building and Construction Catalysts Chemicals Coatings Composites Consumer Goods Defense Dentistry Electrical Energy & Power Engineering Environment Flooring Food Furniture Glass Healthcare Home and Household Care HVAC Industrial Logistics Lubricants Machinery Medical Metals Military Mining Packaging Paper Personal Care Petrochemicals Pharmaceuticals Pipes & Tubes Plastics Polymers Printing Recycling Retail Rubber Sports Textiles Transportation Water Management Wire & Cable Woodworking