29 Nov 2006

High Modulus Ductile (HMD)

With new innovative technologies for automotive body panels, GE Plastics has started a strategic offensive that clearly stands out against the existing polymer solutions in this application. Key advantages include a significantly higher modulus, lower coefficient of thermal expansion (CTE) and extended design freedom for highly integrated and weight saving parts with “Class A” paintable surface quality.

BERGEN OP ZOOM, THE NETHERLANDS — November 29, 2006 — In the 1990s, engineering thermoplastics such as Xenoy* PC/ Polyester and Noryl* PA/PPE blends were key to weight, fuel and cost saving automotive exterior applications. However, since that time the established polymer technologies³as implemented in several serial applications³are bordering on their limits. Automotive manufacturers are asking for polymers with a fit that’s not just for self-colored/clear or off-line/on-line painted body parts of relatively confined dimensions, but also for larger panels and complex, three dimensional units with properties that are no longer met by conventional plastic.

Main requirements include:

• First: Considerable more design freedom for innovative styling, integration of parts, functions and manufacturing steps, as well as pedestrian impact protection

• Second: Flash and gap reduction for enhanced aesthetics, as well as reduced mechanical provisions in the manufacturing and painting process

• Third: Improved planarity, reduced post shrinkage and less warpage allows better dimensional stability

• Forth: On-line and off-line paintability with environmentally friendly paint systems that meet “Class A” surface requirements

To meet these challenges, GE Plastics has developed an innovative material technology that provides noticeably higher performance properties compared to existing plastic material solutions.

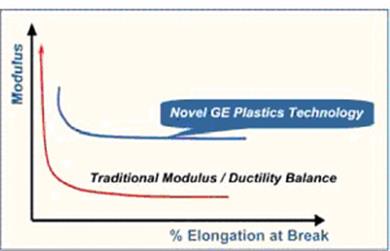

HMD (high modulus ductile) Cycoloy* and Xenoy resins for off-line painted vertical body panels combine a high modulus and low CTE with excellent ductility.

HMD is based on a proprietary nano-filler technology that surpasses existing thermoplastic for automotive body panels. Most obviously, perhaps, it offers an enormous potential for reducing the CTE to values below 5x10-5mm/mm/°C, while at the same time exhibiting less anisotropic behavior compared to classical filler technologies.

The performance of the HMD technology was tested and validated in comprehensive laboratory testing, as well as various close-to–production prototype parts.

Working with a leading German injection molding machines manufacturer, GE Plastics studied the effect of HMD filler technology on the molding and application performance of a close-to-production prototype part versus conventional filler technologies.

The results confirmed the excellent performance of GE Plastic’s new technology.

• CTE values measured below 5x10-5mm/mm/°C

• Painted surface quality exceeds current application

• Dimensional stability meets stretch target

• E-modulus and ductility meet expected values and showed better values as standard filled materials

Based on these positive results, GE Plastics has translated the HMD technology into the Cycoloy resin and Xenoy resin product family, commercializing it as first grade.

Cycoloy resin XCM850

Reinforced PC/ABS with high stiffness and low CTE

Typical properties

| Tensile Modulus, 1mm/min | 4650 M Pa | ISO527 |

| Izod Impact, notched 80*10*4 23°C | 10 kJ/m2 | ISO 180/1A |

| Vicat Softeting Temp, Rate B/50 | 139°C | ISO306 |

| CTE –40°C to 40°C, flow | 4,3 E-05 | ISO 1139-2 |

For more details please refer to datasheet Cycoloy resin XCM850 under geplastics.com.

Cycoloy resin XCM850 is an excellent material for off-line painted exterior body panel applications such as doors, tailgates, fenders and long trim appliqués, etc. For off-line exterior body panels with enhanced requirements for chemical resistance and ductility, Xenoy HMD developmental resin is an excellent choice. The chemical resistance of Xenoy HMD is comparable to standard Xenoy resin, but higher than PC/ABS materials.

GE Plastics will continue to combine its forces in driving HMD material development, enabling the automotive industry to launch its next generation of cars that will meet the market demand. Cycoloy HMD resin and Xenoy HMD resin will support the challenge of improved fuel efficiency by allowing lightweight solutions. Furthermore, it can provide a material solution for greater design freedom and potential cost savings.

Reader enquiries

GE Plastics, Automotive

Plasticslaan 1

4600 AC Bergen op Zoom

Notes for editors

About GE Plastics

GE Plastics (www.geplastics.com)is a global supplier of plastic resins widely used in automotive, healthcare, consumer electronics, transportation, performance packaging, building & construction, telecommunications, and optical media applications. The company manufactures and compounds polycarbonate, ABS, SAN, ASA, PPE, PC/ABS, PBT and PEI resins, as well as the LNP* line of high-performance specialty compounds. GE Plastics, Specialty Film & Sheet manufactures high-performance Lexan sheet and film products used in thousands of demanding applications worldwide. In addition, GE Plastics’ dedicated Automotive organization is an experienced, world-wide competitor, offering leading plastics solutions for five key automotive segments: body panels and glazing; under the hood applications; component; structures and interiors; and lighting. As a Worldwide Partner of the Olympic Games, GE is the exclusive provider of a wide range of innovative products and services that are integral to a successful Games.

* Xenoy, Noryl, Cycoly, LNP and Lexan are trademarks of General Electric Company.

Related images

Editorial enquiries

Anne Clement

GE Plastics, Automotive

Folke Markestein

Marketing Solutions NV

Also available in