5 Apr 2005

Breakthrough thermoplastic composite sheet from GE & AZDEL* improves safety & performance for passenger train components

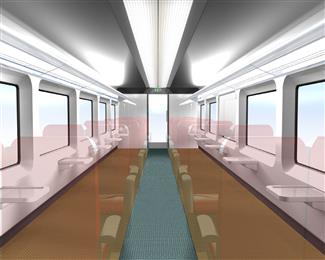

BERGEN OP ZOOM, THE NETHERLANDS - Like a train on a well-run railroad, new product technology from GE Advanced Materials, a unit of the General Electric Company (NYSE: GE), and AZDEL, Inc. has arrived just in time to address rising demand for safer, higher performing materials in the passenger rail industry. The new product, called AZDEL Rail-Lite* composite, is a low-pressure, thermoformable, lightweight composite sheet that exhibits excellent flame, smoke, toxicity, and heat-release performance in large semi-structural panels for train interiors. The new product, called AZDEL Rail-Lite composite, is a low-pressure, thermoformable, lightweight composite sheet that exhibits excellent flame, smoke, toxicity, and heat-release performance in large semi-structural panels for train interiors. GE unveiled the new product technology at the Railway Interiors Expo in Cologne (Nov. 30 – Dec. 2, 2004). AZDEL, Inc. is a 50/50 joint venture of GE and PPG Industries, based in Lynchburg, Virginia, USA.

Comprised of long glass fibers, AZDEL Rail-Lite composite enables sturdy, lightweight components with approximately half of the specific gravity as lower performing composite materials. Roughly half the volume of an AZDEL Rail-Lite composite structure is comprised of air, giving the new material exceptionally low weight. This may help reduce the weight of finished parts – and, therefore, help reduce fuel consumption – for potentially significant cost savings. The new product technology is translatable to other industries, such as aircraft and building and construction. New products based on this technology are now under development at AZDEL and GE.

“Materials technology for passenger trains and other transportation segments has turned a corner with the commercial launch of our new AZDEL Rail-Lite composite,” said Melanie Cook, GE Advanced Materials’ marketing director for Transportation. “No other product that we know of available today can deliver the same outstanding balance of flame, smoke, and toxicity performance with the light weight and excellent mechanical properties of this new material.”

According to Ken Forden, president, AZDEL, Inc., “The synergies of GE’s materials expertise, PPG’s fiber technology, and the patented wet chopped fiber process pioneered by AZDEL, have enabled us to develop a whole new family of advanced composite materials that meet growing global demand for improved flame, smoke, and toxicity performance. AZDEL Rail-Lite composite has been very well received and is the first of several new high-performance products AZDEL and GE plan to introduce in the future.”

When parts formed from AZDEL Rail-Lite composite are exposed to flame, it quickly chars while emitting very low levels of smoke. The char and glass fibers also create a surface barrier to the flame, similar to that of a ceramic material. Because of this, AZDEL Rail-Lite composite will not catch fire and drip, like lower performing competitive products or thermoplastic sheet type materials. This quality is quickly becoming essential for applications on trains, subways, and other mass-transit systems where fires have claimed many lives in the past.

“There have been a number of mass-transit fires around the world that have drawn attention to the need for materials with improved flame, smoke, and toxicity performance,” said Benny David, global industry manager – Transportation Composites, GE Advanced Materials. “The London underground fire in 1987 that killed 31 people; last year’s subway fire in Daegu, Korea where an estimated 120 people perished and more than 130 were injured; and other similar fires, were all tragic events that no one wants to see repeated. Add to this the increasing threat of global terrorism and it’s clear that newer, better flame-retardant materials for trains and other mass-transit systems are needed.”

In addition to its outstanding flame, smoke, and toxicity performance, new AZDEL Rail-Lite composite offers excellent strength, stiffness, and a low coefficient of thermal expansion (CTE). It also provides good duc

Reader enquiries

SABIC

WTC Tower Ten Strawinskylaan 1475

1077 XX Amsterdam

Netherlands

Notes for editors

About GE Advanced Materials

GE Advanced Materials (http://www.geadvancedmaterials.com) is a world leader in providing materials solutions through engineering thermoplastics, silicon-based products and technology platforms, and fused quartz and ceramics. Among its businesses are:

• Plastics – which is a global plastics materials supplier and distributor, serving customers in a variety of industries including aerospace, appliances, automotive, building and construction, data storage and optical media, medical, electrical and electronics devices, telecommunications, computers and peripheral devices, outdoor vehicles and devices, and packaging (http://www.geplastics.com).

• Silicones – which includes GE Toshiba Silicones in the Pacific region and GE Bayer Silicones in Europe, offering silanes, specialty silicones, urethane additives, adhesives, sealants, resins, and elastomers for a variety of industries such as personal care, automotive, tire and rubber, construction, healthcare, electronics, household and institutional, agriculture, textiles, appliances, bedding and furnishings, foam control, and consumer (< href=http://www.gesilicones.com target=_blank>http://www.gesilicones.com).

• Quartz – which provides high-purity quartz and advanced ceramic materials for the semiconductor, telecommunications, lighting, electronics, personal care, water purification, and various other industries (http://www.gequartz.com).

GE (NYSE: GE) is a diversified technology, media, and financial services company dedicated to creating products that make life better. From aircraft engines and power generation to financial services, medical imaging, television programming, and plastics, GE operates in more than 100 countries and employs more than 300,000 people worldwide. For more information, visit the company's website at www.http://www.ge.com.

About GE Advanced Materials Specialty Film & Sheet

GE Advanced Materials’ Specialty Film & Sheet business is a leading supplier of high-performance engineering film and sheet products to global industry. Through this business, GE Advanced Materials offers a variety of film materials for display films, graphic films, coated products, electrical and electronics applications, specialty products, and a range of others. The company’s sheet product line includes an array of high-performance structures – from single- and multi-wall sheet, corrugated materials, and coated sheet products to laminates and combinations of each – to serve customers in several key global sectors.

About AZDEL, Inc.

AZDEL, Inc. is a joint venture of GE Advanced Materials and PPG Industries. The AZDEL business was established in 1972 by PPG, and the 50/50 joint venture was set up with GE in 1986. AZDEL is a global leader in the manufacture and supply of high-performance composite materials serving a wide variety of markets and industries including automotive, transportation interiors, large truck, materials handling, heating, ventilation and air conditioning (HVAC), and building and construction.

* AZDEL and Rail-Lite are trademarks of AZDEL, Inc., a 50/50 joint venture of General Electric Company and PPG Industries.

Related images

Editorial enquiries

Banu Kukner

SABIC

Folke Markestein

Marketing Solutions NV

fmarkestein@marketingsolutions.be

Jim Allison

AH&M Marketing Communications

Also available in