formnext 2019

| Frankfurt am Main, Germany |

19 - 22 Nov 2019

formnext.mesago.com/events/en.html

The leading global exhibition and conference on additive manufacturing and the next generation of intelligent industrial production

Formnext is the leading exhibition and conference dedicated to additive manufacturing and all of its upstream and downstream processes.

Discover the future of your production

It is where experts from a wide range of industry sectors, such as automotive, aerospace, mechanical engineering, medical technology, electrical engineering, and many more, come together to discover additive manufacturing, industrial 3D printing, and innovative production technologies for themselves.

21 Nov 2019

Oerlikon partners with United Launch Alliance to manufacture launch vehicle flight components

Oerlikon AM, the additive manufacturing unit of global technology powerhouse Oerlikon, announces it will provide metal additively manufactured qualification and flight components for United Launch Alliance’s (ULA) next-generation Vulcan Centaur rocket. ULA is the world's most experienced and reliable launch service provider, with more than 130 launches and 100 percent mission success.

Oerlikon AM, the additive manufacturing unit of global technology powerhouse Oerlikon, announces it will provide metal additively manufactured qualification and flight components for United Launch Alliance’s (ULA) next-generation Vulcan Centaur rocket. ULA is the world's most experienced and reliable launch service provider, with more than 130 launches and 100 percent mission success.

20 Nov 2019

Oerlikon AM and Siemens collaborate to digitize additive manufacturing

Oerlikon AM, the additive manufacturing unit of technology group Oerlikon, and Siemens AG announce a strategic agreement in which Siemens will provide Oerlikon AM with digital enterprise solutions that will help Oerlikon accelerate the industrialization of additive manufacturing.

Oerlikon AM, the additive manufacturing unit of technology group Oerlikon, and Siemens AG announce a strategic agreement in which Siemens will provide Oerlikon AM with digital enterprise solutions that will help Oerlikon accelerate the industrialization of additive manufacturing.

19 Nov 2019

Taking the path of most resistance

Ulrik Beste and Martin Nilsson - friends since their school days in a small town 50 miles northwest of Stockholm - are today are at the helm of Uppsala-based VBN Components (VBN), a fast growing company, literally at the cutting edge of materials development and additive manufacturing.

Ulrik Beste and Martin Nilsson - friends since their school days in a small town 50 miles northwest of Stockholm - are today are at the helm of Uppsala-based VBN Components (VBN), a fast growing company, literally at the cutting edge of materials development and additive manufacturing.

19 Nov 2019

Sintavia scales end-to-end applied additive technology

Brian Neff wants to leave nothing to chance. To ensure the quality of the high-value additively manufactured metal parts his company provides for the demanding aerospace and defense sectors, he believes it is imperative to have end-to-end control of the production process – from design and raw materials to final part inspection.

Brian Neff wants to leave nothing to chance. To ensure the quality of the high-value additively manufactured metal parts his company provides for the demanding aerospace and defense sectors, he believes it is imperative to have end-to-end control of the production process – from design and raw materials to final part inspection.

19 Nov 2019

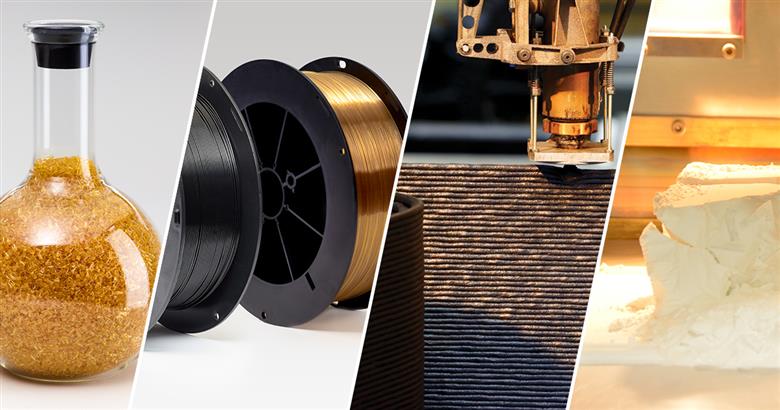

SABIC showcases at Formnext 2019 diverse collaborations that deliver material technologies across the additive manufacturing value chain

SABIC, a global leader in the chemical industry, is spotlighting here at Formnext 2019 (Hall 12.1, B61) its diverse and expanding collaborations that deliver value to customers by providing the company’s specialized materials at various points throughout the global additive manufacturing value chain. The company’s goals for these collaborations are to foster innovation and steadily expand application development opportunities for additively produced parts. To that end, SABIC is well positioned to supply a variety of unique material chemistries that can address critical customer and value chain partner challenges in additive manufacturing.

SABIC, a global leader in the chemical industry, is spotlighting here at Formnext 2019 (Hall 12.1, B61) its diverse and expanding collaborations that deliver value to customers by providing the company’s specialized materials at various points throughout the global additive manufacturing value chain. The company’s goals for these collaborations are to foster innovation and steadily expand application development opportunities for additively produced parts. To that end, SABIC is well positioned to supply a variety of unique material chemistries that can address critical customer and value chain partner challenges in additive manufacturing.

19 Nov 2019

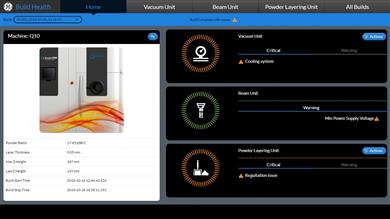

GE Additive releases Arcam EBM Build Performance Analyzer

GE Additive today announced the launch of Arcam EBM Build Performance Analyzer - a new suite of machine health data analytics – and will first be released from December 2019 to Arcam EBM Q10 and Q10plus customers and then from Q1 2020 to Arcam EBM Q20 and Arcam EBM Q20plus customers and then to Arcam EBM Spectra customers through Q2 and Q3 2020.

GE Additive today announced the launch of Arcam EBM Build Performance Analyzer - a new suite of machine health data analytics – and will first be released from December 2019 to Arcam EBM Q10 and Q10plus customers and then from Q1 2020 to Arcam EBM Q20 and Arcam EBM Q20plus customers and then to Arcam EBM Spectra customers through Q2 and Q3 2020.

19 Nov 2019

GE Additive Arcam EBM launches D-material support for Pure Copper and Highly Alloyed Tool Steel

GE Additive Arcam today announced general release of development material (D-material) support for pure copper and highly-alloyed tool steel during 2020.

GE Additive Arcam today announced general release of development material (D-material) support for pure copper and highly-alloyed tool steel during 2020.

19 Nov 2019

GE Additive launches Arcam PRS 30 powder recovery station

GE Additive today unveiled the Arcam PRS 30 – a new, automated powder recovery station to create a closed system to contain powder exposure for operators working in industrial additive manufacturing environments.

GE Additive today unveiled the Arcam PRS 30 – a new, automated powder recovery station to create a closed system to contain powder exposure for operators working in industrial additive manufacturing environments.

19 Nov 2019

GE Additive unveils new Concept Laser M2 Series 5

GE Additive today unveiled the Concept Laser M2 Series 5 at formnext. This latest iteration of the popular M2 machine meets the high expectations for part quality and consistency from customers, especially in the highly-regulated aerospace and medical industries, as they move to serial additive production. The Concept Laser M2 Series 5 will be manufactured at the GE Additive Lichtenfels facility, is available for order now, with delivery expected in Q1 2020.

GE Additive today unveiled the Concept Laser M2 Series 5 at formnext. This latest iteration of the popular M2 machine meets the high expectations for part quality and consistency from customers, especially in the highly-regulated aerospace and medical industries, as they move to serial additive production. The Concept Laser M2 Series 5 will be manufactured at the GE Additive Lichtenfels facility, is available for order now, with delivery expected in Q1 2020.

19 Nov 2019

GE Additive unveils Arcam EBM Spectra L

GE Additive today unveiled the Arcam EBM Spectra™ L at formnext. The Spectra L meets increased demand, especially from the aerospace industry for higher productivity and offers customers a larger build volume, faster speed, married with an integrated system architecture, new machine health analytics and automation features.

GE Additive today unveiled the Arcam EBM Spectra™ L at formnext. The Spectra L meets increased demand, especially from the aerospace industry for higher productivity and offers customers a larger build volume, faster speed, married with an integrated system architecture, new machine health analytics and automation features.

14 Nov 2019

Clariant turns the spotlight on 3D printed end use functional parts and new material for mobility and E&E trends at formnext 2019

As intelligent industrial manufacturing gains a stronger foothold in production alongside the more established customization/prototyping arenas, Clariant returns to this year’s formnext with new solutions to support the growth. A new halogen-free flame retardant 3D printing material takes center stage alongside eye-catching and unique printed end use parts from a range of applications.

As intelligent industrial manufacturing gains a stronger foothold in production alongside the more established customization/prototyping arenas, Clariant returns to this year’s formnext with new solutions to support the growth. A new halogen-free flame retardant 3D printing material takes center stage alongside eye-catching and unique printed end use parts from a range of applications.

13 Nov 2019

Additive Manufacturing research: Experts at Oerlikon, Linde and TU Munich to develop high-strength lightweight aluminum-based alloy

Global technology Group Oerlikon, with vast expertise in materials, has entered into an additive manufacturing (AM) research alliance with Linde, the world’s largest industrial gases company, and the Technical University of Munich (TUM), one of the leading German universities in engineering. The partners aim to develop new high-strength, lightweight aluminum-based alloys that can serve the safety and weight reduction needs of the aerospace and automotive industries. The Bavarian Ministry of Economic Affairs is funding 50% of the EUR 1.7 million research project.

Global technology Group Oerlikon, with vast expertise in materials, has entered into an additive manufacturing (AM) research alliance with Linde, the world’s largest industrial gases company, and the Technical University of Munich (TUM), one of the leading German universities in engineering. The partners aim to develop new high-strength, lightweight aluminum-based alloys that can serve the safety and weight reduction needs of the aerospace and automotive industries. The Bavarian Ministry of Economic Affairs is funding 50% of the EUR 1.7 million research project.