27 Oct 2010

SABIC Press Kit K 2010

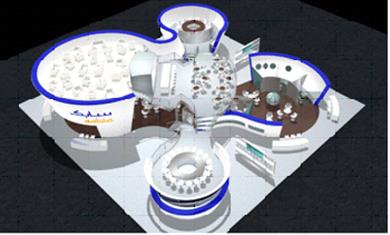

SABIC’s theme for K2010 is Culture of Innovation, demonstrated by investments in Growth, Technology, Sustainability and Customer Focus.

Press Releases

SABIC Showcases Culture of Innovation at K 2010

Bergen op Zoom, the Netherlands – October 27, 2010 – At K 2010, Hall 6, Stand D42, SABIC is showcasing new technologies, expanded capabilities and strong customer relationships that comprise its theme for the show: Culture of Innovation. A key focus is SABIC’s sustainability strategy, underscoring the company’s commitment to addressing worldwide sustainability issues – including energy and greenhouse gas reduction, water conservation and material efficiency. The SABIC stand features an impressive array of materials from its broad and growing portfolio that enable breakthrough applications across major growth sectors such as healthcare, automotive, electronics, packaging, film and alternative energy.

Bergen op Zoom, the Netherlands – October 27, 2010 – At K 2010, Hall 6, Stand D42, SABIC is showcasing new technologies, expanded capabilities and strong customer relationships that comprise its theme for the show: Culture of Innovation. A key focus is SABIC’s sustainability strategy, underscoring the company’s commitment to addressing worldwide sustainability issues – including energy and greenhouse gas reduction, water conservation and material efficiency. The SABIC stand features an impressive array of materials from its broad and growing portfolio that enable breakthrough applications across major growth sectors such as healthcare, automotive, electronics, packaging, film and alternative energy.

SABIC Innovative Plastics Spotlights at K 2010 Chery’s New A3CC Sports Coupe Designed with High-Tech Noryl GTX*, Xenoy*, Stamax® Resins

BERGEN OP ZOOM, The Netherlands – October 29, 2010 – Chery Automobile’s soon to be launched new A3CC sports coupe using SABIC Innovative Plastics’ advanced materials solutions – is highlighted here at K 2010 in SABIC’s stand – Hall 6, Stand D42. The sleek new sports car delivers high-end style and practical performance with the first Noryl GTX* resin front fenders used by a Chinese automotive OEM; a fuel filler door, also molded from Noryl GTX resin; light weight front and rear energy absorbers made from Xenoy* resin; and an undertray, molded from Stamax® long glass-filled polypropylene (LGFPP) compound. These multiple applications on the vehicle illustrate SABIC Innovative Plastics’ breadth of materials technology expertise and demonstrate the environmental and performance benefits of its plastics for world-class auto motive design with broad appeal.

BERGEN OP ZOOM, The Netherlands – October 29, 2010 – Chery Automobile’s soon to be launched new A3CC sports coupe using SABIC Innovative Plastics’ advanced materials solutions – is highlighted here at K 2010 in SABIC’s stand – Hall 6, Stand D42. The sleek new sports car delivers high-end style and practical performance with the first Noryl GTX* resin front fenders used by a Chinese automotive OEM; a fuel filler door, also molded from Noryl GTX resin; light weight front and rear energy absorbers made from Xenoy* resin; and an undertray, molded from Stamax® long glass-filled polypropylene (LGFPP) compound. These multiple applications on the vehicle illustrate SABIC Innovative Plastics’ breadth of materials technology expertise and demonstrate the environmental and performance benefits of its plastics for world-class auto motive design with broad appeal.

SABIC’s smart concept in multi-layer film packaging raises the levels of performance, cost-efficiency and sustainability

Sittard, the Netherlands – October 27, 2010 – SABIC, a leading player in the global plastics industry, today unveiled a pioneering concept in low-density polyethylene and linear-low-density polyethylene (LD/LLDPE) films at the K2010 tradeshow in Düsseldorf, Germany

Sittard, the Netherlands – October 27, 2010 – SABIC, a leading player in the global plastics industry, today unveiled a pioneering concept in low-density polyethylene and linear-low-density polyethylene (LD/LLDPE) films at the K2010 tradeshow in Düsseldorf, Germany

At K 2010 SABIC Innovative Plastics Reaffirms Environmental Commitment with Expanded Sustainability Portfolio and New Verification Program

BERGEN OP ZOOM, The Netherlands – November 1, 2010 – Here at K 2010, in Hall 6, Stand D42, SABIC Innovative Plastics is reaffirming its commitment to the environment with two new announcements: the expansion of its already extensive Sustainability Solutions Portfolio comprised of more than 20 sustainability solution families and hundreds of product grades such as new Noryl*, Cycoloy* and Lexan* EXL resins containing post-consumer recycled (PCR) content; and the introduction of a rigorous new validation process for sustainable materials and applications. The new process includes a Sustainable Product Scorecard, developed in partnership with respected, third-party environmental sustainability consulting firm, GreenOrder. Both announcements illustrate SABIC Innovative Plastics’ commitment to addressing its customers’ diverse environmental needs. This includes the company’s ongoing investments in materials, technologies and processes that help customers worldwide lower their carbon and energy footprints, eliminate waste, and ensure strict compliance with global environmental regulations.

BERGEN OP ZOOM, The Netherlands – November 1, 2010 – Here at K 2010, in Hall 6, Stand D42, SABIC Innovative Plastics is reaffirming its commitment to the environment with two new announcements: the expansion of its already extensive Sustainability Solutions Portfolio comprised of more than 20 sustainability solution families and hundreds of product grades such as new Noryl*, Cycoloy* and Lexan* EXL resins containing post-consumer recycled (PCR) content; and the introduction of a rigorous new validation process for sustainable materials and applications. The new process includes a Sustainable Product Scorecard, developed in partnership with respected, third-party environmental sustainability consulting firm, GreenOrder. Both announcements illustrate SABIC Innovative Plastics’ commitment to addressing its customers’ diverse environmental needs. This includes the company’s ongoing investments in materials, technologies and processes that help customers worldwide lower their carbon and energy footprints, eliminate waste, and ensure strict compliance with global environmental regulations.

SABIC® LDPE UMS pushes the limits in performance, cost-efficiency and sustainability for PE foam applications

Sittard, the Netherlands – November 2, 2010 – SABIC – a leading player in the global plastics industry – today launched its new foam line, SABIC® LDPE Ultra Melt Strength (UMS), at the K2010 tradeshow in Düsseldorf, Germany (Hall 6, Stand D42).

Sittard, the Netherlands – November 2, 2010 – SABIC – a leading player in the global plastics industry – today launched its new foam line, SABIC® LDPE Ultra Melt Strength (UMS), at the K2010 tradeshow in Düsseldorf, Germany (Hall 6, Stand D42).

SABIC Innovative Plastics’ New Extem* UP Resins Crank Up the Heat with Highest Continuous Use Temperature Rating for Unfilled Thermoplastic

BERGEN OP ZOOM, The Netherlands – November 3, 2010 – At K 2010, in Hall 6, Stand D42, SABIC Innovative Plastics is showcasing its global technological leadership with another outstanding achievement: one of the industry’s highest continuous use temperature rating for an unfilled thermoplastic material. New flame-retardant Extem* UP thermoplastic polyimide (TPI) resins are extreme high-heat materials that recently achieved a UL746B relative temperature index (RTI) rating of 240C. By incorporating polyetheretherketone (PEEK) into its proven ultra-performance Extem resin technology, SABIC Innovative Plastics is able to offer customers optimized performance combining the best of both materials. This unique blend technology opens new opportunities for lower-weight, high-temperature continuous use applications such as semiconductor chip trays, connectors for harsh environments, and metal replacement in high-heat oil and gas and aerospace environments. This new breakthrough technology demonstrates once again SABIC Innovative Plastics’ commitment to the proactive development of unique specialty resins that meets the highest performance demands of customers.

BERGEN OP ZOOM, The Netherlands – November 3, 2010 – At K 2010, in Hall 6, Stand D42, SABIC Innovative Plastics is showcasing its global technological leadership with another outstanding achievement: one of the industry’s highest continuous use temperature rating for an unfilled thermoplastic material. New flame-retardant Extem* UP thermoplastic polyimide (TPI) resins are extreme high-heat materials that recently achieved a UL746B relative temperature index (RTI) rating of 240C. By incorporating polyetheretherketone (PEEK) into its proven ultra-performance Extem resin technology, SABIC Innovative Plastics is able to offer customers optimized performance combining the best of both materials. This unique blend technology opens new opportunities for lower-weight, high-temperature continuous use applications such as semiconductor chip trays, connectors for harsh environments, and metal replacement in high-heat oil and gas and aerospace environments. This new breakthrough technology demonstrates once again SABIC Innovative Plastics’ commitment to the proactive development of unique specialty resins that meets the highest performance demands of customers.

SABIC Innovative Plastics’ Tough Lexan* Sheet for Train Window Frames Helps Plexx Stay on Track with Lower Costs and Streamlined Production

BERGEN OP ZOOM, The Netherlands – November 9, 2010 – At K 2010, SABIC Innovative Plastics today announced that its new ultra-tough, flame-retardant (FR) Lexan* F6000 polycarbonate (PC) sheet has been chosen by Plexx AS, a leading Norwegian plastics converter, to thermoform the first European passenger train window frames. The frames will be used in Norwegian State Railways train cabins. This advanced, tailor-made PC material replaces sheet molded composite (SMC) for significantly improved performance and faster cycle times, while avoiding the multiple secondary operations required for SMC. SABIC Innovative Plastics is helping customers succeed in the highly competitive transportation sector with advanced solutions that provide high performance, system cost savings, and superior end-product differentiation vs. thermoset materials. The company is exhibiting at K 2010 in Hall 6, Stand D42.

BERGEN OP ZOOM, The Netherlands – November 9, 2010 – At K 2010, SABIC Innovative Plastics today announced that its new ultra-tough, flame-retardant (FR) Lexan* F6000 polycarbonate (PC) sheet has been chosen by Plexx AS, a leading Norwegian plastics converter, to thermoform the first European passenger train window frames. The frames will be used in Norwegian State Railways train cabins. This advanced, tailor-made PC material replaces sheet molded composite (SMC) for significantly improved performance and faster cycle times, while avoiding the multiple secondary operations required for SMC. SABIC Innovative Plastics is helping customers succeed in the highly competitive transportation sector with advanced solutions that provide high performance, system cost savings, and superior end-product differentiation vs. thermoset materials. The company is exhibiting at K 2010 in Hall 6, Stand D42.

SABIC Ramps up New Business Unit to Provide Advanced Materials Technology Expertise to Middle East and Africa

Bergen op Zoom, the Netherlands – October 27, 2010 – Here at the K Show, Hall 6, Stand D42, the Innovative Plastics strategic business unit of SABIC, today announced the establishment of a new business unit to meet growing customer demand for advanced engineering thermoplastic materials and application development expertise in the Middle East and Africa. This new organization, which is based in Riyadh, Saudi Arabia, demonstrates SABIC’s strong commitment to this increasingly important region – providing customers access to a robust portfolio of more than 40,000 high-performance resins. The new business unit will be led by Richard Crosby, a veteran Innovative Plastics executive and scientist.

Bergen op Zoom, the Netherlands – October 27, 2010 – Here at the K Show, Hall 6, Stand D42, the Innovative Plastics strategic business unit of SABIC, today announced the establishment of a new business unit to meet growing customer demand for advanced engineering thermoplastic materials and application development expertise in the Middle East and Africa. This new organization, which is based in Riyadh, Saudi Arabia, demonstrates SABIC’s strong commitment to this increasingly important region – providing customers access to a robust portfolio of more than 40,000 high-performance resins. The new business unit will be led by Richard Crosby, a veteran Innovative Plastics executive and scientist.

SABIC Innovative Plastics’ New Portfolio of Solutions for Sustainable LED Retrofit Lighting Shines with High-Performance, Style, Long Life at K 2010

BERGEN OP ZOOM, The Netherlands – November 11, 2010 – SABIC Innovative Plastics launched a new portfolio of specialty resins and compounds that can optimize the performance, lifespan and aesthetics of light-emitting diode (LED) retrofit lighting. These materials include non-brominated, non-chlorinated flame-retardant (FR) Lexan* polycarbonate (PC) resin and new white LNP* Konduit* thermally conductive compound for LED heat sinks, which adds style to outstanding heat dissipation for extended bulb life. One hundred and thirteen years after the invention of the light bulb, SABIC Innovative Plastics is developing solutions for the latest technological milestone in the evolution of lighting – with materials that promote adoption of these energy-efficient, long-lasting solutions – one of the broadest offerings for LED lighting customers on the market today.

BERGEN OP ZOOM, The Netherlands – November 11, 2010 – SABIC Innovative Plastics launched a new portfolio of specialty resins and compounds that can optimize the performance, lifespan and aesthetics of light-emitting diode (LED) retrofit lighting. These materials include non-brominated, non-chlorinated flame-retardant (FR) Lexan* polycarbonate (PC) resin and new white LNP* Konduit* thermally conductive compound for LED heat sinks, which adds style to outstanding heat dissipation for extended bulb life. One hundred and thirteen years after the invention of the light bulb, SABIC Innovative Plastics is developing solutions for the latest technological milestone in the evolution of lighting – with materials that promote adoption of these energy-efficient, long-lasting solutions – one of the broadest offerings for LED lighting customers on the market today.

SABIC Innovative Plastics’ New Noryl GTX* Conductive Resins Offer Greater Dimensional Stability for Larger Automotive Body Panels

BERGEN OP ZOOM, The Netherlands – November 16, 2010 – At K 2010, SABIC Innovative Plastics launched its latest high-tech thermoplastic offering – a new family of Noryl GTX* resins – to give global automotive OEMs and tiers a major design advantage. These new conductive blends of polyamide (PA) and modified polyphenylene ether (PPE) cut coefficient of thermal expansion (CTE) by 20 to 40 percent vs. previous grades for increased dimensional stability and improved gap and flush management, giving automotive designers greater freedom to create larger top-quality, high-precision body panels than previously feasible, and which integrate into existing processes, including higher-heat online painting systems. These high-performance materials underscore SABIC Innovative Plastics’ strategic focus on helping automotive customers create differentiated designs that also promote system cost reduction and sustainability through weight-out.

BERGEN OP ZOOM, The Netherlands – November 16, 2010 – At K 2010, SABIC Innovative Plastics launched its latest high-tech thermoplastic offering – a new family of Noryl GTX* resins – to give global automotive OEMs and tiers a major design advantage. These new conductive blends of polyamide (PA) and modified polyphenylene ether (PPE) cut coefficient of thermal expansion (CTE) by 20 to 40 percent vs. previous grades for increased dimensional stability and improved gap and flush management, giving automotive designers greater freedom to create larger top-quality, high-precision body panels than previously feasible, and which integrate into existing processes, including higher-heat online painting systems. These high-performance materials underscore SABIC Innovative Plastics’ strategic focus on helping automotive customers create differentiated designs that also promote system cost reduction and sustainability through weight-out.

SABIC Expands Random Copolymer PP Grades for Excellent Aesthetics and Enhanced High Performance in Cast Film

Sittard, the Netherlands – October 8, 2010 – SABIC, a global plastics industry leader, today announced an important expansion of its polypropylene (PP) resin portfolio: two new random copolymer PP grades for cast film and biaxially oriented polypropylene (BOPP) film applications. The new grades – SABIC® PP 622L and SABIC® PP 621P– are engineered to meet growing customer demand for advanced film technologies such as multi-layer constructions, and for improved aesthetics and versatility. They provide significant advantages over homopolymers in a wide range of packaging applications, enabling converters to produce film with high clarity and exceptional sealing and puncture resistance performance. Applications include food packaging, lamination film, hygiene packaging, stationary film, and flower/textile packaging.

Sittard, the Netherlands – October 8, 2010 – SABIC, a global plastics industry leader, today announced an important expansion of its polypropylene (PP) resin portfolio: two new random copolymer PP grades for cast film and biaxially oriented polypropylene (BOPP) film applications. The new grades – SABIC® PP 622L and SABIC® PP 621P– are engineered to meet growing customer demand for advanced film technologies such as multi-layer constructions, and for improved aesthetics and versatility. They provide significant advantages over homopolymers in a wide range of packaging applications, enabling converters to produce film with high clarity and exceptional sealing and puncture resistance performance. Applications include food packaging, lamination film, hygiene packaging, stationary film, and flower/textile packaging.

SABIC® Vestolen A RELY Achieves New Standards for Sustainability, Performance, Cost Effectiveness in HDPE Pipe Applications

Sittard, the Netherlands – September 20, 2010 – At the Plastic Pipes XV Conference in Vancouver, Canada (stand 6) SABIC, a global plastics industry leader, today introduced the new SABIC® Vestolen A RELY family of tough, sustainable and cost-effective bimodal high-density polyethylene (HDPE) materials for pressure pipe applications. The SABIC® Vestolen A RELY portfolio offers converters considerable energy savings and enables environmentally responsible pipe installation. Further demonstrating its commitment to sustainable technologies, the company also presented today its revolutionary new Strain Hardening method, a fast, cost-efficient and highly accurate method for evaluating the slow crack growth resistance behaviour of HDPE. This Strain Hardening method avoids the use of detergents - that can pose an environmental hazard – and avoids the use of valuable drinking water.

Sittard, the Netherlands – September 20, 2010 – At the Plastic Pipes XV Conference in Vancouver, Canada (stand 6) SABIC, a global plastics industry leader, today introduced the new SABIC® Vestolen A RELY family of tough, sustainable and cost-effective bimodal high-density polyethylene (HDPE) materials for pressure pipe applications. The SABIC® Vestolen A RELY portfolio offers converters considerable energy savings and enables environmentally responsible pipe installation. Further demonstrating its commitment to sustainable technologies, the company also presented today its revolutionary new Strain Hardening method, a fast, cost-efficient and highly accurate method for evaluating the slow crack growth resistance behaviour of HDPE. This Strain Hardening method avoids the use of detergents - that can pose an environmental hazard – and avoids the use of valuable drinking water.

SABIC Innovative Plastics’ Ultem* Resin Composite Gives Crane Stellar Performance, Rapid Thermoforming for New Composite Aerospace Board

BERGEN OP ZOOM, The Netherlands – September 21, 2010 — At the Aircraft Interiors Expo Americas, Sept. 14-16, 2010, SABIC Innovative Plastics have launched a new breakthrough technology for semi-structural aircraft interior parts featuring its high-flying Ultem* polyetherimide (PEI) resin. New Ultem composite aerospace board (CAB) sheets, co-developed and manufactured with Crane & Co., the global leader in specialty paper, provide a superior alternative to thermoset aramid fiber-reinforced honeycomb composites. The Ultem CAB sheets can be quickly thermoformed, offer a broad range of high-performance properties, are recyclable, and offer great potential to be refurbished with a newly developed decorative film layer while still meeting Federal Aviation Administration (FAA) requirements to extend useful life. The sheets are currently being trialed by a major airline. Together with the expertise of Crane, SABIC Innovative Plastics has launched yet another technology that delivers a cost-effective solution to the global aircraft industry.

BERGEN OP ZOOM, The Netherlands – September 21, 2010 — At the Aircraft Interiors Expo Americas, Sept. 14-16, 2010, SABIC Innovative Plastics have launched a new breakthrough technology for semi-structural aircraft interior parts featuring its high-flying Ultem* polyetherimide (PEI) resin. New Ultem composite aerospace board (CAB) sheets, co-developed and manufactured with Crane & Co., the global leader in specialty paper, provide a superior alternative to thermoset aramid fiber-reinforced honeycomb composites. The Ultem CAB sheets can be quickly thermoformed, offer a broad range of high-performance properties, are recyclable, and offer great potential to be refurbished with a newly developed decorative film layer while still meeting Federal Aviation Administration (FAA) requirements to extend useful life. The sheets are currently being trialed by a major airline. Together with the expertise of Crane, SABIC Innovative Plastics has launched yet another technology that delivers a cost-effective solution to the global aircraft industry.

SABIC Innovative Plastics Boosts Ultem* Resin Capacity by 35% at New World-Scale Cartagena Facility to Meet Growing European, World Demand

BERGEN OP ZOOM, The Netherlands – September 23, 2010 — Launching a new chapter in the history of one of its most renowned materials, SABIC Innovative Plastics today cut the ribbon at its new Ultem* polyetherimide (PEI) resin production facility here in Cartagena. This much-anticipated event marks a 35 percent increase in Ultem resin capacity for European and global customers. The state-of-the-art 300 million Euros facility, which is SABIC Innovative Plastics’ second Ultem resin plant, will provide customers with higher supply dependability. The plant also encompasses scalable capacity for producing ultra-high-performance Extem* resin grades and specialty intermediates (anhydrides). Proprietary process chemistry and cutting-edge manufacturing technologies will improve operating reliability and flexibility while minimizing the environmental impact of by-products. This major investment demonstrates the company’s unyielding commitment to reliable, scalable supplies of its Ultem and Extem resin grades, whose outstanding performance is driving ever-greater demand from global customers.

BERGEN OP ZOOM, The Netherlands – September 23, 2010 — Launching a new chapter in the history of one of its most renowned materials, SABIC Innovative Plastics today cut the ribbon at its new Ultem* polyetherimide (PEI) resin production facility here in Cartagena. This much-anticipated event marks a 35 percent increase in Ultem resin capacity for European and global customers. The state-of-the-art 300 million Euros facility, which is SABIC Innovative Plastics’ second Ultem resin plant, will provide customers with higher supply dependability. The plant also encompasses scalable capacity for producing ultra-high-performance Extem* resin grades and specialty intermediates (anhydrides). Proprietary process chemistry and cutting-edge manufacturing technologies will improve operating reliability and flexibility while minimizing the environmental impact of by-products. This major investment demonstrates the company’s unyielding commitment to reliable, scalable supplies of its Ultem and Extem resin grades, whose outstanding performance is driving ever-greater demand from global customers.

SABIC Innovative Plastics Expands Specialty Polypropylene Compounding to Meet Rising Auto OEM Call for Leading-Edge Materials Technologies

BERGEN OP ZOOM, The Netherlands – October 13, 2010 – SABIC Innovative Plastics today announced that it is adding state-of-the-art specialty polypropylene (PP) compounding to its Bay St. Louis, Miss. site in the first quarter of 2011. The site will use its existing infrastructure and adopt new processes to produce SABIC® PP compounds and SABIC STAMAX® long glass fiber-reinforced PP composites. Adding specialty PP to the site’s compounding capabilities enables the company to provide a broader range of high-performance materials to its customers in North America and to help satisfy demand for specialty compounds – which is a market recovering fast from the recent downturn. Investment in this highly automated and technologically sophisticated process supports SABIC Innovative Plastics’ commitment to meeting both automotive OEM needs for lightweight, high-performance materials that can significantly reduce fuel consumption and emissions vs. competitive products, and non-automotive needs in key segments such as fluid handling and appliance.

SABIC presents growing product portfolio at the 2010 SEPAWA Congress in Fulda, Germany

Sittard, the Netherlands – October 14, 2010 – SABIC will present two new product groups from its Performance Chemicals Strategic Business Unit - Ethanolamines and Ethoxylates - at the 57th SEPAWA Congress & European Detergents Conference (EDC) to be held in Fulda, Germany, from October 13-15, 2010.

Sittard, the Netherlands – October 14, 2010 – SABIC will present two new product groups from its Performance Chemicals Strategic Business Unit - Ethanolamines and Ethoxylates - at the 57th SEPAWA Congress & European Detergents Conference (EDC) to be held in Fulda, Germany, from October 13-15, 2010.

Reader enquiries

SABIC

WTC Tower Ten Strawinskylaan 1475

1077 XX Amsterdam

Netherlands

Notes for editors

SABIC Innovative Plastics is a leading, global supplier of engineering thermoplastics with a 75-year history of breakthrough solutions that solve its customers’ most pressing challenges. Today, SABIC Innovative Plastics is a multi-billion-dollar company with operations in more than 35 countries and approximately 9,000 employees worldwide. The company continues to lead the plastics industry with customer collaboration and continued investments in new polymer technologies, global application development, process technologies, and environmentally responsible solutions that serve diverse markets such as automotive, electronics, building & construction, transportation, and healthcare. The company’s extensive product portfolio includes thermoplastic resins, coatings, specialty compounds, film, and sheet. SABIC Innovative Plastics (www.sabic-ip.com) is a wholly owned subsidiary of Saudi Basic Industries Corporation (SABIC), one of the world’s top six petrochemicals manufacturers.

* Trademarks of SABIC Innovative Plastics IP BV.

About SABIC

Saudi Basic Industries Corporation (SABIC) ranks among the world’s top six petrochemical companies. The company is among the world’s market leaders in the production of polyethylene, polypropylene and other advanced thermoplastics, glycols, methanol and fertilizers.

SABIC recorded a net profit of SR 9 billion (US$ 2.4 billion) in 2009. Sales revenues for 2009 totaled SR 103 billion (US$ 27 billion). Total assets stood at SR 297 billion (US$ 79.2 billion) at the end of 2009.

SABIC’s businesses are grouped into Chemicals, Polymers, Performance Chemicals, Fertilizers, Metals and Innovative Plastics. SABIC has significant research resources with six dedicated Technology & Innovation Centers in Saudi Arabia, Europe, the USA and India. The company operates in more than 40 countries across the world with 33,000 employees worldwide.

The company has 19 world-scale complexes in Saudi Arabia. Elsewhere, SABIC manufactures on a global scale in the Americas, Europe and Asia Pacific. SABIC’s overall production has increased from 35 million metric tons in 2001 to 59 million metric tons in 2009.

Headquartered in Riyadh, SABIC was founded in 1976 when the Saudi Arabian Government decided to use the hydrocarbon gases associated with its oil production as the principal feedstock for production of chemicals, polymers and fertilizers. The Saudi Arabian Government owns 70 percent of SABIC shares with the remaining 30 percent held by private investors in Saudi Arabia and other Gulf Cooperation Council countries.

About SABIC in Europe

In Europe, SABIC has 13 world-scale production facilities which manufacture innovative plastics, polyethylenes, polypropylenes and chemical products. Throughout Europe, SABIC employs approximately 6000 people.

The main European offices for three of SABIC’s strategic business units are located in The Netherlands - Innovative Plastics (Bergen op Zoom), Polymers (Sittard) and Chemicals (Sittard). They operate an extensive network of local sales offices and logistical hubs throughout Europe which are also responsible for the sales of products manufactured elsewhere in the world.

SABIC’s European research facilities form part of the global Technology and Innovation organization and can be found in the Netherlands (Geleen and Bergen op Zoom) and Spain (Cartagena).

Media Notes

• As an acronym, SABIC should be all caps whenever it appears in print.

• ® Trademark of SABIC

Related documents

Editorial enquiries

Helen Vandebovenkamp

SABIC

Helen.vandebovenkamp@sabic-ip.com

Kevin Noels

Marketing Solutions NV