13 Jul 2023

SABIC expands specialty materials portfolio with new LNP™ STAT-KON™ compounds to help advance ADAS radar and improve safety

SABIC, a global leader in the chemical industry, today announced the expansion of its specialty materials portfolio for advanced driver assistance systems (ADAS) to further strengthen occupant and pedestrian safety. The company’s two new LNP™ STAT-KON™ compounds are well suited for ADAS radar absorbers and can help propel adoption of millimeter wave (mmWave) radar, which significantly improves sensor accuracy and range. By providing robust and high-resolution information about remote objects, mmWave radar could enhance driving safety and support the trend toward the use of autonomous vehicles.

SABIC, a global leader in the chemical industry, today announced the expansion of its specialty materials portfolio for advanced driver assistance systems (ADAS) to further strengthen occupant and pedestrian safety. The company’s two new LNP™ STAT-KON™ compounds are well suited for ADAS radar absorbers and can help propel adoption of millimeter wave (mmWave) radar, which significantly improves sensor accuracy and range. By providing robust and high-resolution information about remote objects, mmWave radar could enhance driving safety and support the trend toward the use of autonomous vehicles.

13 Jul 2023

SABIC launches two PP-based, intumescent FR materials well suited for extruding and thermoforming large, complex EV battery pack components

SABIC, a global leader in the chemical industry, today introduced SABIC® PP compound H1090 resin and STAMAX™ 30YH611 resin, two breakthrough materials well-suited for sheet extrusion and thermoforming that offer a unique alternative to traditional sheet metal forming, compression and injection molding, allowing customers to form large, complex structural parts.

SABIC, a global leader in the chemical industry, today introduced SABIC® PP compound H1090 resin and STAMAX™ 30YH611 resin, two breakthrough materials well-suited for sheet extrusion and thermoforming that offer a unique alternative to traditional sheet metal forming, compression and injection molding, allowing customers to form large, complex structural parts.

6 Jul 2023

SABIC launches new PCR-based NORYL™ portfolio to help customers reduce carbon footprint

SABIC, a global leader in the chemical industry, today announced its new PCR-based NORYL™ resin technology, formulated using 25 percent or more post-consumer recycled (PCR) content and aimed at providing additional, sustainable material options for customers. The technology was validated through the commercialization of several grades, including NORYL NH5120RC3 resin containing 30 percent PCR content, which helps to lower its global warming potential (GWP) by 10 percent compared to the incumbent, fossil-based grade.

SABIC, a global leader in the chemical industry, today announced its new PCR-based NORYL™ resin technology, formulated using 25 percent or more post-consumer recycled (PCR) content and aimed at providing additional, sustainable material options for customers. The technology was validated through the commercialization of several grades, including NORYL NH5120RC3 resin containing 30 percent PCR content, which helps to lower its global warming potential (GWP) by 10 percent compared to the incumbent, fossil-based grade.

29 Jun 2023

SABIC launches Material Finder website featuring rich functionality and high-value data to give customers a digital edge when selecting specialty thermoplastics

SABIC, a global leader in the chemical industry, is debuting its new SABIC Material Finder website to help customers and prospective customers conveniently search, compare, evaluate and select specialty thermoplastic materials for a wide range of applications. The new website, which provides robust functionality and high-value, multi-point data, offers several unique features to casual and registered users. Any user can review information on more than 2,000 SABIC specialty resins, copolymers, and compounds – one of the largest portfolios in the industry. For registered users, SABIC’s Specialties business’ product material data is available for easy download in multiple computer-assisted engineering (CAE) platform formats to simplify the material selection process. They can also request color-matching services or place orders for color chips directly from the website.

SABIC, a global leader in the chemical industry, is debuting its new SABIC Material Finder website to help customers and prospective customers conveniently search, compare, evaluate and select specialty thermoplastic materials for a wide range of applications. The new website, which provides robust functionality and high-value, multi-point data, offers several unique features to casual and registered users. Any user can review information on more than 2,000 SABIC specialty resins, copolymers, and compounds – one of the largest portfolios in the industry. For registered users, SABIC’s Specialties business’ product material data is available for easy download in multiple computer-assisted engineering (CAE) platform formats to simplify the material selection process. They can also request color-matching services or place orders for color chips directly from the website.

22 Jun 2023

SABIC debuts LNP™ THERMOCOMP™ compound to help facilitate the adoption of LDS antennas and advance device production

SABIC, a global leader in the chemical industry, today introduced new LNP™ THERMOCOMP™ WF006V compound, which is well suited for laser direct structuring (LDS) of antennas that are integrated into the housings and covers of consumer electronics devices, appliances and other electronic components. The new material can help facilitate the adoption of LDS antennas to replace incumbent options such as flexible printed circuit (FPC) antennas by enabling customers to create complex and miniaturized designs, accelerate production and reduce system costs. The glass-fiber-reinforced compound provides a tensile modulus more than two times higher than that of unfilled polybutylene terephthalate (PBT) or polycarbonate (PC) resin, and could be used for molding small, thin-wall parts. It also delivers good surface quality for attractive aesthetics, and good signal gain and LDS performance. Compared to traditional materials, the LNP THERMOCOMP WF006V compound offers better chemical resistance and hydrolytic stability, and lower warpage.

SABIC, a global leader in the chemical industry, today introduced new LNP™ THERMOCOMP™ WF006V compound, which is well suited for laser direct structuring (LDS) of antennas that are integrated into the housings and covers of consumer electronics devices, appliances and other electronic components. The new material can help facilitate the adoption of LDS antennas to replace incumbent options such as flexible printed circuit (FPC) antennas by enabling customers to create complex and miniaturized designs, accelerate production and reduce system costs. The glass-fiber-reinforced compound provides a tensile modulus more than two times higher than that of unfilled polybutylene terephthalate (PBT) or polycarbonate (PC) resin, and could be used for molding small, thin-wall parts. It also delivers good surface quality for attractive aesthetics, and good signal gain and LDS performance. Compared to traditional materials, the LNP THERMOCOMP WF006V compound offers better chemical resistance and hydrolytic stability, and lower warpage.

14 Jun 2023

SABIC receives 2023 ACC Sustainable Leadership Award for circularity achievements with ocean bound plastic based solutions

SABIC, a global leader in the chemical industry, has been awarded with a 2023 Sustainability Leadership Award for Exemplary Achievements in Circularity by the American Chemistry Council (ACC), recognizing the company’s pioneering collaborations to bring ocean bound plastic (OBP) back into a circular material.

SABIC, a global leader in the chemical industry, has been awarded with a 2023 Sustainability Leadership Award for Exemplary Achievements in Circularity by the American Chemistry Council (ACC), recognizing the company’s pioneering collaborations to bring ocean bound plastic (OBP) back into a circular material.

13 Jun 2023

SABIC expands chemically resistant LNP™ CRX copolymer portfolio to help industrial and mobility customers design for durability

SABIC, a global leader in the chemical industry, will feature new LNP™ CRX copolymer resins at The smarter E Europe 2023 show (Booth #B6.115), this week in Munich, Germany. These specialized resins give customers in the mobility and industrial sectors new material options that can resist both harsh chemicals and challenging environmental conditions. The new specialized polycarbonate (PC) copolymer-based LNP CRX products deliver the chemical resistance expected from this portfolio, in combination with exceptional weatherability (UL74C F1 rating, low-temperature ductility and ability to withstand high levels of heat and humidity). These properties may help enhance the durability of components such as charging sockets for electric vehicles (EV) and housings for outdoor battery storage equipment.

SABIC, a global leader in the chemical industry, will feature new LNP™ CRX copolymer resins at The smarter E Europe 2023 show (Booth #B6.115), this week in Munich, Germany. These specialized resins give customers in the mobility and industrial sectors new material options that can resist both harsh chemicals and challenging environmental conditions. The new specialized polycarbonate (PC) copolymer-based LNP CRX products deliver the chemical resistance expected from this portfolio, in combination with exceptional weatherability (UL74C F1 rating, low-temperature ductility and ability to withstand high levels of heat and humidity). These properties may help enhance the durability of components such as charging sockets for electric vehicles (EV) and housings for outdoor battery storage equipment.

8 Jun 2023

SABIC to showcase at The smarter E Europe 2023 its growing portfolio of specialty materials to support energy advancements

SABIC, a global leader in the chemical industry, will highlight at The smarter E Europe 2023 (Booth #B6.115) its innovative material solutions well-suited for the electric vehicle supply equipment (EVSE), battery, solar and wind industries. SABIC’s specialty resins, compounds, and copolymers – including bio-based, recycled and upcycled solutions – can make a meaningful contribution to sustainability, performance enhancements and new designs for applications across these rapidly expanding sectors. As an example of this effort, at the show SABIC will be launching new LNP™ ELCRES™ CRX grades that can provide a combination of flame retardance (FR) and impact and chemical resistance to EVSE components. SABIC’s materials, backed by expert application design, development, and support services, can help customers achieve their goals and build a brighter energy future.

SABIC, a global leader in the chemical industry, will highlight at The smarter E Europe 2023 (Booth #B6.115) its innovative material solutions well-suited for the electric vehicle supply equipment (EVSE), battery, solar and wind industries. SABIC’s specialty resins, compounds, and copolymers – including bio-based, recycled and upcycled solutions – can make a meaningful contribution to sustainability, performance enhancements and new designs for applications across these rapidly expanding sectors. As an example of this effort, at the show SABIC will be launching new LNP™ ELCRES™ CRX grades that can provide a combination of flame retardance (FR) and impact and chemical resistance to EVSE components. SABIC’s materials, backed by expert application design, development, and support services, can help customers achieve their goals and build a brighter energy future.

25 May 2023

SABIC expands ULTEM™ portfolio with colorable, high-flow, reinforced grades for connectors and other thin-wall components

SABIC, a global leader in the chemical industry, today announced the expansion of its high-heat ULTEM™ resin portfolio with new glass fiber-reinforced grades that deliver high flow, custom colorability and high strength, and are well suited for thin-wall components like fiber optic and electrical connectors. New low-viscosity ULTEM 2120, 2220 and 2320 resins exhibit exceptional flow characteristics that empower designers to create miniaturized, high-precision components with complex geometries. For molders, the high flow capabilities of these materials offer the flexibility to lower injection pressures or mold thinner walls at the same pressure, while avoiding short shots. In contrast to other high-flow glass-reinforced ULTEM materials, these new grades maintain the existing color range of existing ULTEM 2X10/2X00 resins and can be custom colored for connector identification and product branding. Furthermore, compared to competitive polysulfones, the ULTEM 2X20 grades can produce more-durable and -reliable parts, thanks to their higher mechanical strength.

SABIC, a global leader in the chemical industry, today announced the expansion of its high-heat ULTEM™ resin portfolio with new glass fiber-reinforced grades that deliver high flow, custom colorability and high strength, and are well suited for thin-wall components like fiber optic and electrical connectors. New low-viscosity ULTEM 2120, 2220 and 2320 resins exhibit exceptional flow characteristics that empower designers to create miniaturized, high-precision components with complex geometries. For molders, the high flow capabilities of these materials offer the flexibility to lower injection pressures or mold thinner walls at the same pressure, while avoiding short shots. In contrast to other high-flow glass-reinforced ULTEM materials, these new grades maintain the existing color range of existing ULTEM 2X10/2X00 resins and can be custom colored for connector identification and product branding. Furthermore, compared to competitive polysulfones, the ULTEM 2X20 grades can produce more-durable and -reliable parts, thanks to their higher mechanical strength.

24 May 2023

SABIC and Solarge showcase development and commercialization of lightweight, circular solar panels

SABIC, a global leader in the chemical industry, has participated in the successful development of lightweight, circular photovoltaic (PV) panels in conjunction with Solarge, an innovative manufacturer of circular lightweight solar panels. This collaboration was showcased during the opening event of Solarge’s new production facility in Weert, The Netherlands on 22nd May. Representatives from SABIC and Solarge, along with other industry leaders, attended the ceremony that was also attended by Rob Jetten, Dutch Minister for Climate & Energy, and Kadri Simson, European Commissioner for Energy.

SABIC, a global leader in the chemical industry, has participated in the successful development of lightweight, circular photovoltaic (PV) panels in conjunction with Solarge, an innovative manufacturer of circular lightweight solar panels. This collaboration was showcased during the opening event of Solarge’s new production facility in Weert, The Netherlands on 22nd May. Representatives from SABIC and Solarge, along with other industry leaders, attended the ceremony that was also attended by Rob Jetten, Dutch Minister for Climate & Energy, and Kadri Simson, European Commissioner for Energy.

18 May 2023

SABIC to feature at sensors converge 2023 award-winning, reflow solderable EXTEM™ resin that can be used for optical lenses

SABIC, a global leader in the chemical industry, will highlight at Sensors Converge 2023 (Booth #1337) its award-winning EXTEM™ RH1016UCL resin and other high-performance thermoplastics that can facilitate the adoption of cutting-edge sensor technologies for advanced driver assistance systems (ADAS) and related applications. EXTEM RH1016UCL resin, which won a 2023 Gold Edison Award, is well suited for ADAS camera near-infrared (IR) lenses, optical transceiver lenses and optical connectors.

SABIC, a global leader in the chemical industry, will highlight at Sensors Converge 2023 (Booth #1337) its award-winning EXTEM™ RH1016UCL resin and other high-performance thermoplastics that can facilitate the adoption of cutting-edge sensor technologies for advanced driver assistance systems (ADAS) and related applications. EXTEM RH1016UCL resin, which won a 2023 Gold Edison Award, is well suited for ADAS camera near-infrared (IR) lenses, optical transceiver lenses and optical connectors.

11 May 2023

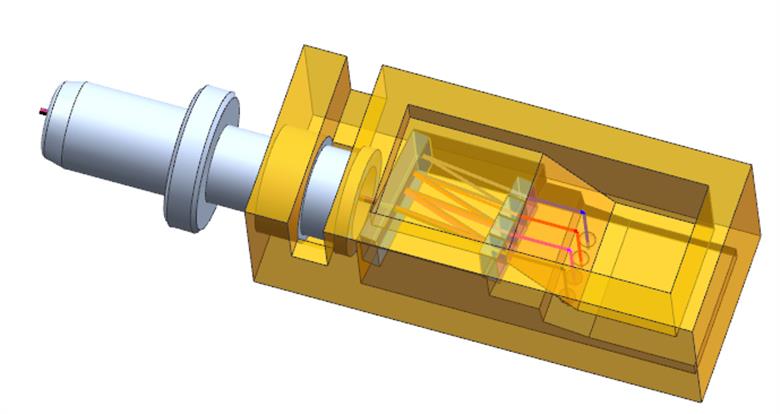

Blovelight selects SABIC’s ULTEM™ resin for its integrated, single-mode WDM modules, helping to expand data center capacity

SABIC, a global leader in the chemical industry, collaborated with China’s Blovelight, Ltd., to develop one of the first integrated, single-mode fiber optic lens arrays that are well-suited for a wavelength-division multiplexing (WDM) module. A WDM module enables simultaneous transmission of multiple wavelengths of light over a single fiber, achieving a significant increase in bandwidth capacity. This innovative design uses SABIC’s ULTEM™ resin, a near-infrared (IR)-transparent, high-heat polyetherimide (PEI) material, to mold an integrated connector (previously metal) and receiving lens array (previously glass) and provide a housing for the WDM component. By enabling part integration and avoiding secondary operations, the SABIC resin helps to make single-mode WDM communications more affordable. Blovelight’s module not only reduces costs vs. individual parts made with glass or metal, but also streamlines manufacturing and assembly.

SABIC, a global leader in the chemical industry, collaborated with China’s Blovelight, Ltd., to develop one of the first integrated, single-mode fiber optic lens arrays that are well-suited for a wavelength-division multiplexing (WDM) module. A WDM module enables simultaneous transmission of multiple wavelengths of light over a single fiber, achieving a significant increase in bandwidth capacity. This innovative design uses SABIC’s ULTEM™ resin, a near-infrared (IR)-transparent, high-heat polyetherimide (PEI) material, to mold an integrated connector (previously metal) and receiving lens array (previously glass) and provide a housing for the WDM component. By enabling part integration and avoiding secondary operations, the SABIC resin helps to make single-mode WDM communications more affordable. Blovelight’s module not only reduces costs vs. individual parts made with glass or metal, but also streamlines manufacturing and assembly.