9 Nov 2001

New Plastic-Metal Hybrid Material from Rhodia Engineering Plastics

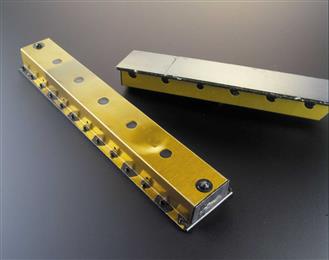

Rhodia Engineering Plastics has developed a range of application concepts focusing on hybrid solutions that combine metals and engineering plastics to high-load bearing (semi-) structural components. The technology is targeted especially at automotive applications, where it brings further benefits such as greater integration depth, weight and cost savings, enhanced energy absorption, and added-value appearance.

Existing plastic/metal solutions can be divided in open and closed rib structures. While open rib designs, where thin metallic sections are moulded over with thermoplastic ribs, provide a good strength-to-cost ratio, their effective mechanical strength and stiffness is highly dependent on the direction of the applied load. This results in complex mould requirements, which must be met by means of sophisticated hot runner technology and/or the use of very low-viscosity resins. Furthermore, the open rib approach cannot be used for applications that need to be safely protected from dirt and water penetration.

In contrast, closed rib and related hollow designs have a more balanced high stiffness and strength regardless of the load direction, that is both in tensile stress and in compression areas. In addition, the hollow sections can be used to integrate various further functions. Rhodia has been investigating three different closed hybrid technologies – Metal Over Moulding (MOM), Plastic & Metal Assembling (PMA), and Metal & Gas or Water Assisted Injection Moulding (MGAIM or MWAIM) – each providing a number of distinct advantages depending on specific application requirements.

In MOM, one or more metal inserts are directly moulded over with an engineering thermoplastic resin. The final reinforcing design is then created in a second step by one or several plastic covers welded on. The resulting hollow section(s) within the structure can serve to integrate cables, flow channels or fluid containers, for instance replacing the need of a separate cooling water expansion tank in automotive front-ends. While MOM components will be somewhat heavier than open rib designs, this is easily compensated by their superior load-bearing, energy absorption and integration capabilities. The time and cost for the additional injection mould and the jointing process is justified by lower mould complexity, lower injection pressures, and lower mould wear.

PMA also involves two process steps, by combining a rigid, ribbed injection moulded plastic part with a metal section by means of clips, rivets and/or ultrasonic welding.

Again, this requires additional capital expenditure, but the space within the final product opens a wide potential for cost and weight saving, functional part consolidation. The mechanical strength compares well with that of open rib structures at lower overall costs.

In MGAIM or MWAIN, the complete hybrid component is manufactured in a single integrated process, by over-moulding a metal part and then coring the plastic material by use of the gas or water assisted technique. The result is a very stiff and lightweight, energy absorbing structure with outstanding surface appearance (no sink marks). The cored-out sections lend themselves to functional integration. Gas and water assisted injection moulding involve some additional cost, but are state-of-the-art, and the mould technology is even simpler yet. Particularly, the freedom of design offered by MGAIM and MWAIN clearly exceeds that of any deep-drawing metal, leading the way to a number of high-end applications replacing expensive aluminium or pure steel components while also minimising the number of jointing and assembly steps. Rhodia sees a wide range of automotive applications for these three technologies, from structural front ends and instrument panel carriers to highly integrated door modules as well as seat shells and an array of smaller applications, such as brake pedals.

Rhodia supports its customers worldwide through eight technical application development centres with comprehensive material advice, process optimisation for in

Reader enquiries

Rhodia Engineering Plastics

Avenue Ramboz

F-69192 Saint-Fons Cedex

France

Notes for editors

Rhodia Engineering Plastics, headquartered in Lyon, France, is the world’s second largest producer of polyamide engineering thermoplastic materials. The company has a sales network that spans the world, with manufacturing plants and technical development centres in Europe, North America, South America and Asia. For further details about the company, visit Rhodia Engineering Plastics’ website at www.rhodia-ep.com

Rhodia is one of the world's leaders in specialty chemicals providing products and services to the automotive, healthcare, fragrance, apparel, electronics, personal care and environmental markets. Rhodia is listed on the Paris and New York stock exchanges, employs 30,000 people worldwide and generated net sales of Euro 7.4 billion in 2000. For further details about the Group, visit Rhodia’s website at: www.rhodia.com

Related images

Editorial enquiries

Christine Bourguignon

Rhodia Engineering Plastics