25 Oct 2001

PolyOne offers Grolsch® total solution for ceramic bottle-stopper replacement

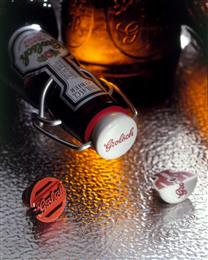

DÜSSELDORF, October 25, 2001 - For many beer drinkers the ceramic re-sealable bottle closures used in some of the premium brands, such as Grolsch®, will be well known. However, this is an expensive bottle design and relies on the bottles being returned. The ceramic stopper, which is non-recyclable, is quite brittle and can be damaged during the return process. Furthermore, the printed logo requiring an additional production operation, can fade or wear away.

The key technical challenge facing Grolsch, a leading European brand, was to re-design one using polymers that retained the traditional appearance of a ceramic stopper but employing materials that improved productivity. The permanence of the logo was also highly important. Of course, the finished molded product had to preserve the visual and tactile qualities of the original.

The Grolsch design team, the German mold-maker Foboha and the Dutch processor Reobijn, collaborated for over a year with engineers from PolyOne Th. Bergmann, the company’s compounder in Gaggenau, Germany, to develop, test and perfect the materials that could be injection molded to replace the ceramic stopper and the printed logo. A particularly demanding challenge, successfully overcome after several trials, was matching the red color of the Grolsch logo.

Finally, MAXXAM® mineral filled, accurately color-matched red polypropylene (PP) was chosen for the main body and logo of the replacement stopper together with an unfilled white PP to form the skin via a 2-shot injection molding process. Both formulations were developed and produced by SO.F.TER., PolyOne’s joint venture partner in Italy.

This highly effective solution emphasises the skill of PolyOne’s engineers; collaborating closely with the Grolsch design team, Foboha the mold-maker and the processor Reobijn stresses PolyOne’s ability to really help people work wonders with polymers. The team successfully designed a new stopper more durable, less expensive and more efficient to produce. And, an additional value-added is there is no discernible difference as far as the all-important consumer is concerned.

PolyOne is featuring the company’s vast portfolio of products for the plastics industry and end-use applications for a broad array of market segments in the new hall 6 stand 6C40 here at the ‘K’ show, the industry’s largest international triennial exhibition staged from October 25 to November 1.

® MAXXAM is a trademark of PolyOne Corporation

® Grolsch is a trademark of Grolsch Bierbrouwerij Nederland

Reader enquiries

PolyOne Corporation

33587 Walker Road

Cleveland

Ohio

U.S.A.

Notes for editors

About PolyOne:

PolyOne Corporation, with revenues of approximately $3 billion, is an international polymer services company with operations in thermoplastic compounds, specialty resins, specialty polymer formulations, engineered films, color and additive systems, elastomer compounding and thermoplastic resin distribution.

Headquartered in Cleveland, Ohio, PolyOne has more than 9,000 employees at 80 manufacturing sites in North America, Europe, Asia and Australia, and joint ventures in North America, South America, Europe, Asia and Australia. Information on the Company’s products and services can be found at www.polyone.com.

Related images

The new Grolsch beer bottle stopper developed by Grolsch, Reobijn, PolyOne and Foboha is more durable, less expensive and more efficient to produce. However, there is no discernible difference as far as the all-important consumer is concerned.

Editorial enquiries

Servé Tonino

Servé Tonino

EMG

Alan Flower

EMG