13 May 2014

Moog Unveils its Largest Radial Piston Pump for Industrial Applications

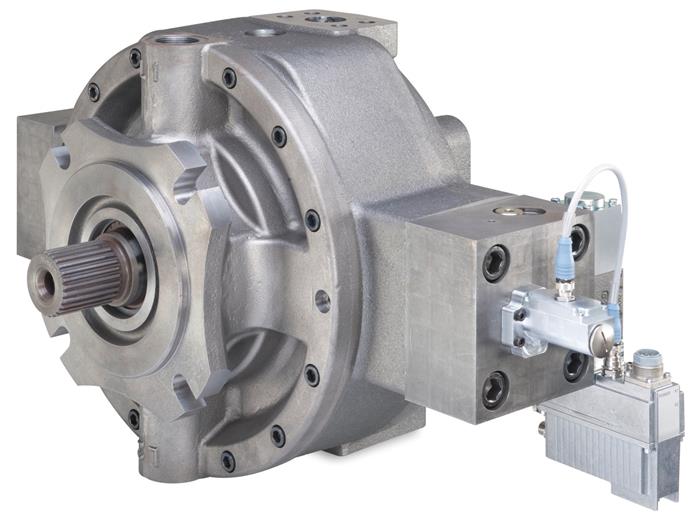

East Aurora, NY, USA, May 13, 2014 - Moog (NYSE: MOG.A and MOG.B), a designer and manufacturer of high performance motion control solutions, has extended its range of variable-displacement radial piston pumps, with the RKP 250 for displacements up to 250 cm³ per revolution. The largest pump in Moog’s RKP series, the RKP 250 is intended for applications requiring high system pressures, such as metal forming, presses, injection molding and other types of industrial machinery. It is capable of delivering continuous pressures up to 350 bar (5000 psi). The Radial Piston Pump is known for its robust design and reliability even in extreme environments.

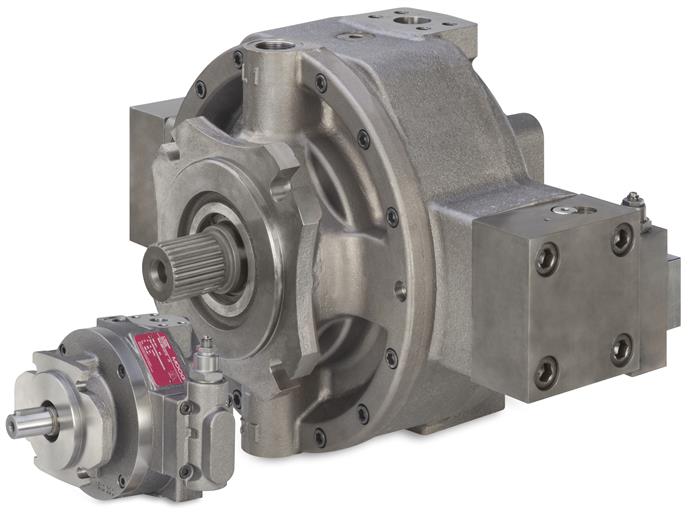

For machine applications where even higher displacements are required, the RKP 250 can be configured in a double-pump arrangement with full torque available across all displacements up to 500 cm³. It also can be combined with other RKP pumps and pumps with standard SAE interfaces (A, B, and C). All RKPs have short axial dimensions, making them ideal for compact multi-pump arrangements.

The RKP 250 provides highly dynamic control of hydraulic flow and pressure. Designed to be used in open-circuit systems, its large suction port and flow-optimized suction path ensure robust suction behavior, a high speed limit, and low noise emission. The pump has a maximum speed of 1800 rpm at an inlet pressure of 0.8 bar absolute (11,6 psi abs), enabling it to operate in machines located at high altitudes without the need for a pre-load pump.

The new piston pump incorporates a nine-piston rotary group. The design of the pistons provides a very low pressure ripple and noise emission behavior.

As with the smaller models in the RKP range, the RKP 250 is equipped with Moog’s proven, robust control system with a sliding stroke ring. The exclusive use of ferrous metals with hardened, wear-resistant contact surfaces leads to outstanding longevity in use. Special versions are available for use with water-glycol (HFC) and synthetic esters (HFD) fluids.

An RKP-D version of the pump, with highly dynamic electro-hydraulic control of flow and pressure through advanced digital on-board electronics, can be configured easily with the Moog Pump Configuration Software. Status information, set values and actual values are displayed graphically for quick and easy performance monitoring, troubleshooting and tuning. As part of Moog’s modular design concept, various compensator options are available including: Pressure (F2), combined pressure and flow (R1), fixed displacement (B1), and dual displacement (N1) compensators. The RKP 250 will also be available in explosion-proof versions.

Reader enquiries

Moog

William-Moog-Strasse 1

71034 Böblingen

Germany

Notes for editors

About Moog

Moog Inc. is a worldwide designer, manufacturer and integrator of precision control components and systems. Moog Industrial Group designs and manufactures high performance motion control solutions combining electric, hydraulic, and hybrid technologies with expert consultative support in a range of applications including energy production and generation machinery, industrial production machinery and simulation and test equipment. We help performance-driven automotive manufacturers, aerospace manufacturers, testing labs and global automotive racing teams to design and develop their next-generation equipment. Moog Industrial Group, with fiscal year 2013 sales of USD 592 million and over 40 locations worldwide, is part of Moog Inc. (NYSE:MOG.A and MOG.B) which has sales of USD 2.61 billion. For more information please visit www.moog.com/test.

Related images

Editorial enquiries

Marie Laure Gelin

Moog

Anouk Luykx

EMG