26 Apr 2007

GE Launches FST-Compliant Ultem* 9085 Resin with Improved Flow Properties for Thinner, Lighter-Weight Aircraft Interior Parts

New High-Tech Resin from GE Plastics Raises the Bar for Aerospace Industry Compliance, Top Performance, and Outstanding Customer Benefits

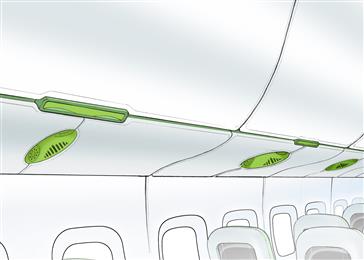

BERGEN OP ZOOM, THE NETHERLANDS — April 26, 2007 — To help the aerospace industry boost fuel efficiency, performance, and safety, GE Plastics today announced new flame-retardant Ultem* 9085 resin for aircraft interiors. This new material offers better flow and ductility than GE’s Ultem 9075 resin – the previous industry standard – to enable thinner-wall parts with excellent impact strength. Further comparing the two materials, new Ultem 9085 resin can reduce part weight by 5 to 15 percent via thinner walls, supporting the goal of lower fuel consumption. At the same time, Ultem 9085 resin delivers the highest modulus of any Ultem resin grade, providing enhanced stiffness to ensure excellent application durability. These greatly improved properties make the new GE product a top choice for demanding applications such as decompression grilles, window reveals, and personal service units.

According to Joseph F. Jahn, president and CEO of Vaupell, a Seattle, Wash.-based molder and Tier 1 aircraft supplier, “Vaupell has worked closely with GE Plastics for several decades supporting the development of resins for the aerospace industry. GE’s new Ultem 9085 resin material demonstrates distinct improvements in processability and physical properties performance compared to the company’s Ultem 9075 resin.”

Like all Ultem resin grades, the new material is inherently flame-retardant, offering full flame/smoke/toxicity (FST) compliance including OSU heat release of less than 55/55. Ultem 9085 resin provides up to 25 percent improvement in ductility and a threefold improvement in flow compared to Ultem 9075 resin, enabling a reduction in both part weight and the amount of resin required. It also delivers good chemical resistance. The new material is lighter in color than its predecessor, making it easier to achieve specific aesthetic effects.

According to The International Air Transport Association, for every kilogram of weight that is removed from a single aisle plane, approximately US$372/year is saved in fuel costs; the average life expectancy for this type of aircraft is approximately 20 years1. In 2005, 10,580 single-aisle airplanes were required worldwide to service the airline industry, and this number is expected to reach 21,470 by 2025. Likewise, the combined number of regional jets, and single-aisle, twin aisle, and large airplanes is expected to double by the year 20252.

“The aerospace industry is constantly looking for new ways to reduce part weight for better fuel efficiency, and using thinner-wall parts are a great approach,” said Ann Delvin, product manager, High Performance Products (HPP) at GE Plastics. “We improved upon our workhorse grade, Ultem 9075 resin, with a new material that allows suppliers to create large, thin-wall parts with excellent impact resistance and stiffness. Ultem 9085 resin can play an important role in decreasing weight while delivering high performance in a wide range of applications.”

For more information on GE’s materials for the aircraft industry, please visit the GE Plastics’ website at www.geplastics.com or contact Benny David, industry manager, Transportation for the Americas at +1 413-448-5175 (benny.david@ge.com); John Darlington, industry manager, Transportation for Europe +31-164-29-2227 (john.darlington@ge.com); or Matt Stoelton, industry manager, Transportation for the Pacific at +81-3-3568-1540 (mathew.stoelton@ge.com).

Reader enquiries

GE Plastics

Plasticslaan 1

4600 AC Bergen op Zoom

Netherlands

Notes for editors

About GE Plastics

GE Plastics (www.geplastics.com) is a global supplier of plastic resins widely used in automotive, healthcare, consumer electronics, transportation, performance packaging, building & construction, telecommunications, and optical media applications. The company manufactures and compounds polycarbonate, ABS, SAN, ASA, PPE, PC/ABS, PBT and PEI resins, as well as the LNP* line of high-performance specialty compounds. GE Plastics, Specialty Film & Sheet manufactures high-performance Lexan* sheet and film products used in thousands of demanding applications worldwide. In addition, GE Plastics’ dedicated Automotive organization is an experienced, world-wide competitor, offering leading plastics solutions for five key automotive segments: body panels and glazing; under the hood applications; component; structures and interiors; and lighting. As a Worldwide Partner of the Olympic Games, GE is the exclusive provider of a wide range of innovative products and services that are integral to a successful Games.

* Ultem, LNP, and Lexan are trademarks of General Electric Company.

Related images

Editorial enquiries

Helen Vandebovenkamp

GE Plastics

Folke Markestein

Marketing Solutions NV