20 Nov 2006

GE’s New Ultem* 5000B Film Offers High-Performance, Cost-Effective Option for Range of Electrical/Electronic Applications

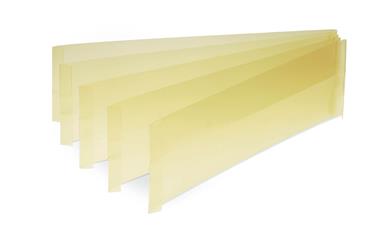

BERGEN OP ZOOM, THE NETHERLANDS — November 20, 2006 — For electrical/electronics (E/E) manufacturers that previously faced the dilemma of choosing between the high cost of specifying polyimide (PI) to achieve desired performance, or downgrading an application by using lower-performing polyethylene napthalate (PEN) or polyester (PET), there is now a solution. New Ultem* 5000B film from GE Plastics offers excellent high performance coupled with cost-effectiveness. Based on GE’s Ultem polyetherimide (PEI) resin, this material’s high temperature and flame resistance, low moisture absorption and excellent dielectric properties make it an excellent candidate for E/E applications such as insulating tapes and laminates, diaphragms and voice coils for loudspeakers, high temperature bar code labels and flat flexible heaters. Ultem 5000B film is available in black and amber and in gauges 25µm - 750µm.

“This new GE film is what the market has been waiting for,” said Max Cattani, GE industry manager for high-performance E/E films, Europe. “Ultem 5000B film gives E/E manufacturers a combination of high performance and cost-effectiveness– reducing the need to overspecify materials or compromise on properties. And this new grade is highly versatile in terms of processing and range of potential applications.”

The following are the key high-performance properties of Ultem 5000B film:

The new GE film offers a wide choice of processing, including thermoforming, drilling, die-cutting, cold-forming, laminating, metal sputtering, and ultrasonic welding. It is heat-sealable to itself and other materials. In contrast, PI standard grades cannot be thermoformed and Aramid Paper releases dust during some processes.

For more information on GE’s Ultem 5000B film, please follow this link to the GE Plastics website: www.geplastics.com.

Reader enquiries

SABIC

WTC Tower Ten Strawinskylaan 1475

1077 XX Amsterdam

Netherlands

Notes for editors

About GE Plastics

GE Plastics (www.geplastics.com) is a global supplier of plastic resins widely used in automotive, healthcare, consumer electronics, transportation, performance packaging, building & construction, telecommunications, and optical media applications. The company manufactures and compounds polycarbonate, ABS, SAN, ASA, PPE, PC/ABS, PBT and PEI resins, as well as the LNP* line of high-performance specialty compounds. GE Plastics, Specialty Film & Sheet manufactures high-performance Lexan* sheet and film products used in thousands of demanding applications worldwide. In addition, GE Plastics’ dedicated Automotive organization is an experienced, world-wide competitor, offering leading plastics solutions for five key automotive segments: body panels and glazing; under the hood applications; component; structures and interiors; and lighting. As a Worldwide Partner of the Olympic Games, GE is the exclusive provider of a wide range of innovative products and services that are integral to a successful Games.

* Ultem, LNP and Lexan are trademarks of General Electric Company.

Related images

Editorial enquiries

Banu Kukner

SABIC

Folke Markestein

Marketing Solutions NV