26 Nov 2003

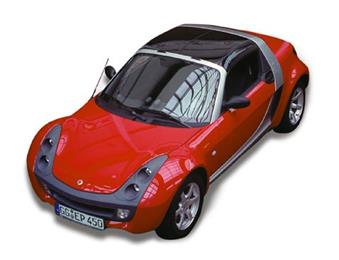

SPE PRESENTS GRAND AWARD TO SMART™ ROADSTER FOR INNOVATIVE ROOF MODULE MADE WITH LEXAN® SLX FILM

--Smart and GE Plastics Win Best-In-Show Honors for “Paintless” Technology at 33rd Annual SPE Innovation Awards Program--

BERGEN OP ZOOM, The Netherlands – Nov. 19, 2003 – Smart GmbH, a business unit of Daimler Chrysler AG, received the Grand Award for the LEXAN® SLX film roof module on their new Smart™ Roadster at the 33rd Annual Society of Plastics Engineers (SPE) International Innovation Awards Program held on Monday, Nov. 17, in Livonia, Mich. In addition, the module earned First Place for Body Exterior Innovation. The SPE Innovation Awards Program is the largest, and most prestigious, engineering awards event of its kind, and is considered to be the auto industry’s premier recognition event.

Challenged to recognize “plastics super heroes that have broken the barriers of automotive plastics innovation,” SPE judges – a blue ribbon panel of automotive and industry experts, journalists, and analysts – selected the “paintless” LEXAN SLX film roof module as the “best of the best” from entries in five categories: Body Exterior, Body Interior, Materials, Power Train and Processing Technology.

“This is a great honor for our customer and for us,” said V. Umamaheswaran (UV), global industry manager, GE Plastics Automotive. “The Smart Roadster roof module is a great example of how LEXAN SLX film can offer styling differentiation through a very high gloss, wet look, while reducing the weight of the roof system by up to 50 percent.”

Other features of the LEXAN SLX film roof module that were cited by the awards committee include a Class A finish without paint, excellent gloss and color retention, and chemical and scratch resistance. This film also offers superior thermoforming characteristics. In addition, another high-performance GE thermoplastic - XENOY® PC/PBT resin – is used in the body panels aboard the smart Roadster to help reduce weight, lower cost and increase impact resistance.

“We’re very pleased to be recognized by the SPE for this application,” said John Carrington, global marketing director, GE Plastics Automotive. “As a European vehicle, the Smart Roadster demonstrates our commitment to innovation by offering global customers the most advanced resin and application technology. This ‘self-protecting’ polymer can give automobiles of the future a long lasting, durable and attractive finish, while saving an estimated $300 to 400 million dollars of future investment for OEMs by eliminating the need to paint.”

LEXAN SLX Resin Hard Top

The roof module of the new Smart Roadster consists of a three-layer, co-extruded LEXAN SLX film. This weatherable, polymeric film can produce Class A molded-in color surfaces without the need for painting or clear coating. LEXAN SLX film can be applied over a variety of thermoplastic and thermoset substrates through an in-mold decoration process. This revolutionary film is the result of ongoing R&D at GE Plastics for a weatherable polymer system designed to eliminate the need for paint shops and painting processes in automotive exterior applications.

LEXAN SLX Film Performance

Tests conducted by GE show that this hard-surface thermoplastic has the potential to withstand the rigors of both road conditions and car wash systems. When tested over 25,000 kJ/m2 of Xenon arc, a test that is used as an equivalent to over 10 years of Florida exposure, LEXAN SLX film retained 95 percent of its gloss. When back-molded with a PC/PBT resin and subjected to various OEM paint specification tests, LEXAN SLX film was found in most cases to perform better or equal to exterior paint systems. Some of the more strikingly positive results were in tests on scratch resistance and resistance to automotive fluids and aggressive agents such as brake fluid and acid rain.

The hard top of the Smart Roadster consists of two halves. Both roof halves weigh only 5 kg respectively and can be removed and stowed in the rear luggage compartment quickly and easily. The hard top is manufactured by ArvinMeritor™ Light Vehicle Systems in Gifhorn, Germany

Smart GmbH was established in April 1994, and is a wholly owned subsidiary of Daimler Chrysler AG Innovative Group.

The GE Plastics Automotiv

Reader enquiries

GE PlasticsPlasticslaan 1

4600 AC Bergen op Zoom

Netherlands

Helen Vandebovenkamp

helen.vandebovenkamp@ge.com

Tel: +31 164 29 20 97

Fax: +31 164 29 10 66

Netherlands

Notes for editors

GE Plastics is a leading producer of engineering thermoplastics with major production facilities worldwide. GE Plastics materials, including LEXAN polycarbonate, are used in a wide variety of applications such as CDs and DVDs, automobile parts, computer housings, cookware, outdoor signage, cell phones, bullet-resistant shielding and building materials. Through its LNP Engineering Plastics business, the company is a worldwide leader in the custom compounding of engineering thermoplastics. GE Plastics is also a global distributor of sheet, film, rod and tube products through GE Polymershapes and GE Structured Products. In 2003, GE Plastics is celebrating the 50th Anniversary of LEXAN polycarbonate resin, discovered in 1953 by GE chemist Dr. Daniel W. Fox. The company's web site is located at www.geplastics.com, and to learn more about LEXAN resin visit www.gelexan.com.

LEXAN and XENOY are Registered Trademarks of General Electric Company.

Smart is a Trademark of Smart GmbH.

ArvinMeritor is a Trademark of ArvinMeritor OE, LLC.

Related images

Editorial enquiries

Banu Kukner

SABIC

Brigitta de Vries

Marketing Solutions NV