25 Sep 2006

Press Kit GE Plastics, Brno

18 - 22 September 2006

GE Plastics Boldly Imagines The Future In Europe

BERGEN OP ZOOM, THE NETHERLANDS – May 30, 2006 - GE Plastics is a global supplier of engineering thermoplastic resins widely used in automotive, healthcare, consumer electronics, transportation, performance packaging, building & construction, telecommunications, and optical media applications. The company manufactures and compounds PC, ABS, ASA, PPO, PC/ABS, PBT and PEI resins, as well as the LNP* line of high-performance specialty compounds. GE Plastics, Specialty Film & Sheet manufactures high-performance Lexan* sheet and film products used in thousands of demanding applications worldwide.

GE Plastics’ New Custom Xpress Small-Lot Color Service Offers Delivery in Six Days or Less

BERGEN OP ZOOM, THE NETHERLANDS — June 16, 2006 — Made-to-order products and fast delivery used to be mutually exclusive. Now, with GE Plastics’ new Custom Xpress color service, customers can get the precise color of GE’s Lexan* or Cycoloy* resin they require in six business days or less. The service allows customers to avoid the drawbacks of self-coloring, such as investment in costly production equipment, while providing the world-leading color-matching capabilities of GE Plastics. The Web-based ordering system gives customers the flexibility to make changes up to eight hours prior to production. And GE’s fully digital global color database ensures consistency worldwide and from batch to batch.

BERGEN OP ZOOM, THE NETHERLANDS — June 16, 2006 — Made-to-order products and fast delivery used to be mutually exclusive. Now, with GE Plastics’ new Custom Xpress color service, customers can get the precise color of GE’s Lexan* or Cycoloy* resin they require in six business days or less. The service allows customers to avoid the drawbacks of self-coloring, such as investment in costly production equipment, while providing the world-leading color-matching capabilities of GE Plastics. The Web-based ordering system gives customers the flexibility to make changes up to eight hours prior to production. And GE’s fully digital global color database ensures consistency worldwide and from batch to batch.

GE’s New Lexan* DMX Polycarbonate Resins Deliver Outstanding Scratch Resistance for Demanding Electronic Applications

BERGEN OP ZOOM, THE NETHERLANDS — November 14, 2006 — The keypads, housings, and other wear parts for mobile phones, computers, and digital cameras can take a real beating from constant handling. Although polycarbonate (PC) is a favorite choice for these components, until now it has been necessary to hard-coat the resin to prevent abrasion and maintain a good surface appearance. But secondary hard coating means extra cost, additional processing time, and potential environmental impact. To help solve this challenge, GE Plastics has developed a new family of Lexan* PC resins featuring outstanding scratch resistance. Compared to standard PC, GE’s Lexan DMX resins provide improved surface hardness without the need for hard coating. These materials are excellent candidates for transparent applications such as soft keys, infrared lenses, bezels, and screens.

GE’s Flame Retardant (FR) Flexible Noryl* Resins Now Recognized Under UL1581 as an Acceptable Wire Coating Material Candidate for 80 °C, 90 °C & 105 °C Applications

BERGEN OP ZOOM, THE NETHERLANDS — November 14, 2006 — GE Plastics recently announced that various grades of its flame-retardant Flexible Noryl* resin for wire coating and insulation have been listed by Underwriters Laboratories (UL) under the UL1581 reference standard for electrical wires, cables, and flexible cords, for up to 105 °C end-use temperature rating. As a result, proposed wire and cable products incorporating high-performance Flexible Noryl resins only need to undergo short-term aging testing vs. a 150-day long-term aging test, speeding time to market. The new GE materials have already proven themselves in the automotive and consumer electronics industries, and, with this new UL listing, are poised for rapid growth in appliance wiring applications.

BERGEN OP ZOOM, THE NETHERLANDS — November 14, 2006 — GE Plastics recently announced that various grades of its flame-retardant Flexible Noryl* resin for wire coating and insulation have been listed by Underwriters Laboratories (UL) under the UL1581 reference standard for electrical wires, cables, and flexible cords, for up to 105 °C end-use temperature rating. As a result, proposed wire and cable products incorporating high-performance Flexible Noryl resins only need to undergo short-term aging testing vs. a 150-day long-term aging test, speeding time to market. The new GE materials have already proven themselves in the automotive and consumer electronics industries, and, with this new UL listing, are poised for rapid growth in appliance wiring applications.

GE’s Xylex* Resin Helps William Levene Spice Up the Award-Winning Jamie Oliver Flavour Shaker with Custom Color

BERGEN OP ZOOM, THE NETHERLANDS — May 31, 2006 — As any chef will tell you, success in the kitchen depends on choosing the best ingredients. So when U.K. chef Jamie Oliver began work with William Levene Ltd. on the development of a brand new tool for mixing and crushing ingredients, the housewares supplier found the right material – Xylex* resin from GE Plastics. The wildly popular Jamie Oliver Flavour Shaker, which allows cooks to quickly crush, mix, and extract flavor from whole spices for rubs and marinades, takes advantage of the GE resin’s heat resistance, transparency, durability, resistance to staining, and custom colorability.

BERGEN OP ZOOM, THE NETHERLANDS — May 31, 2006 — As any chef will tell you, success in the kitchen depends on choosing the best ingredients. So when U.K. chef Jamie Oliver began work with William Levene Ltd. on the development of a brand new tool for mixing and crushing ingredients, the housewares supplier found the right material – Xylex* resin from GE Plastics. The wildly popular Jamie Oliver Flavour Shaker, which allows cooks to quickly crush, mix, and extract flavor from whole spices for rubs and marinades, takes advantage of the GE resin’s heat resistance, transparency, durability, resistance to staining, and custom colorability.

Ted Brewer’s Vivo2 Violins Hit a High Note with Stunning Color Effects, Courtesy of GE’s Lexan* Visualfx* Resin

BERGEN OP ZOOM, THE NETHERLANDS, — July 3, 2006 — Crystal blue, rich violet, and water-clear polycarbonate (PC) with a touch of diamond sparkle – these are not your traditional violins. Crafted by Ted Brewer, an established U.K. designer of transparent violins, the ultramodern Vivo2 line features GE Plastics’ Lexan* Visualfx* special effects resin for stunning visual impact combined with high performance. Ted, who originally hand-carved his instruments from acrylic block, turned to GE Plastics when increasing market demand prompted a move to injection molding. GE Plastics color experts helped Ted turn his vision for the Vivo2 into an eye-catching reality.

BERGEN OP ZOOM, THE NETHERLANDS, — July 3, 2006 — Crystal blue, rich violet, and water-clear polycarbonate (PC) with a touch of diamond sparkle – these are not your traditional violins. Crafted by Ted Brewer, an established U.K. designer of transparent violins, the ultramodern Vivo2 line features GE Plastics’ Lexan* Visualfx* special effects resin for stunning visual impact combined with high performance. Ted, who originally hand-carved his instruments from acrylic block, turned to GE Plastics when increasing market demand prompted a move to injection molding. GE Plastics color experts helped Ted turn his vision for the Vivo2 into an eye-catching reality.

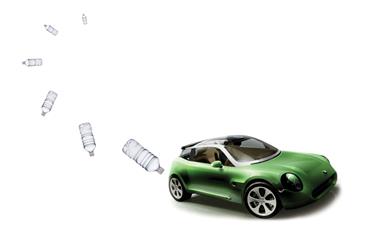

GE Plastics Launches New Family of ecomagination* Products That Dramatically Cut CO2, Post-Consumer Waste & Petrochemical Use

BERGEN OP ZOOM, THE NETHERLANDS — July 27, 2006 — Complementing Japan’s environmental leadership in responsible automotive manufacturing, GE Plastics today celebrates two significant additions to its ecomagination* portfolio: Valox iQ* and Xenoy iQ* resins. The new products were developed as a result of a successful two-year initiative at GE Plastics that examined the company’s manufacturing processes to redefine how its products can be made to be cleaner and more environmentally responsible than traditional materials. Valox iQ and Xenoy iQ resins are the essential elements of an environmentally progressive resin portfolio developed as part of GE’s ecomagination initiative.

BERGEN OP ZOOM, THE NETHERLANDS — July 27, 2006 — Complementing Japan’s environmental leadership in responsible automotive manufacturing, GE Plastics today celebrates two significant additions to its ecomagination* portfolio: Valox iQ* and Xenoy iQ* resins. The new products were developed as a result of a successful two-year initiative at GE Plastics that examined the company’s manufacturing processes to redefine how its products can be made to be cleaner and more environmentally responsible than traditional materials. Valox iQ and Xenoy iQ resins are the essential elements of an environmentally progressive resin portfolio developed as part of GE’s ecomagination initiative.

GE Plastics ecomagination* Initiative Backgrounder

Overview

* In May 2005, GE (www.ge.com) announced its ecomagination* initiative, a major worldwide effort to drive new business opportunities by helping customers solve their toughest environmental challenges.

* The focus of GE’s ecomagination initiative is on accelerating the company’s materials, energy, technology, manufacturing, and infrastructure capabilities to develop global environmental solutions. These include lighter and stronger materials, fuel cells, solar energy, hybrid locomotives, lower-emission aircraft engines, and water purification technologies.

GE Helps LTK’s AV Cable Meet Requirements for Halogen-Free Wiring Parts

Hong Kong-based LTK Industries, one of the most successful wire and cable manufacturers in China, has played a pivotal role in transforming Hong Kong and China from net importers of wire and cable into major suppliers and exporters. A strong supporter of environmental responsibility, LTK was the first wire and cable company in the world to be awarded Restricted Substance Compliance Solutions (RSCS) approval from UL®, indicating its products meet the requirements of the European Union’s Restriction in the use of certain Hazardous Substances (RoHS) in electrical/electronic equipment.

Hong Kong-based LTK Industries, one of the most successful wire and cable manufacturers in China, has played a pivotal role in transforming Hong Kong and China from net importers of wire and cable into major suppliers and exporters. A strong supporter of environmental responsibility, LTK was the first wire and cable company in the world to be awarded Restricted Substance Compliance Solutions (RSCS) approval from UL®, indicating its products meet the requirements of the European Union’s Restriction in the use of certain Hazardous Substances (RoHS) in electrical/electronic equipment.

Ultem* Resin Helps Give BTicino Security Devices

BTicino was one of the first Italian manufacturers to produce electrical components designed with a modern edge. This attitude is reflected in the substantial innovations of their technology and production process automation. These focus attention towards providing solutions to contemporary household needs and uses. BTicino caters to residential (wiring devices and video and audio door entry systems), office (distribution and installation system of cables, power, data, and sound), and home automation (network technology, radio and cable) markets with the assistance of Ultem Resin.

BTicino was one of the first Italian manufacturers to produce electrical components designed with a modern edge. This attitude is reflected in the substantial innovations of their technology and production process automation. These focus attention towards providing solutions to contemporary household needs and uses. BTicino caters to residential (wiring devices and video and audio door entry systems), office (distribution and installation system of cables, power, data, and sound), and home automation (network technology, radio and cable) markets with the assistance of Ultem Resin.

William Levene Shakes up the Kitchenware Industry with GE’s Xylex* Resin

Established for nearly 60 years, William Levene is a premier supplier of kitchen products, cookware, and gadgets throughout the UK. The firm also exports to 42 countries worldwide. Known for clever and innovative designs, William Levene worked with well-known television Chef Jamie Oliver to commercialize his invention of a gadget for quickly preparing flavorful marinades and rubs for foods. To meet the requirements of the Flavour Shaker application, William Levene selected Xylex* resin from GE Plastics.

Established for nearly 60 years, William Levene is a premier supplier of kitchen products, cookware, and gadgets throughout the UK. The firm also exports to 42 countries worldwide. Known for clever and innovative designs, William Levene worked with well-known television Chef Jamie Oliver to commercialize his invention of a gadget for quickly preparing flavorful marinades and rubs for foods. To meet the requirements of the Flavour Shaker application, William Levene selected Xylex* resin from GE Plastics.

GE Helps OPEL Set the Trend for Ingenuity with the New 2007 Corsa

When OPEL designed the new Corsa, the company wanted to create a trend-setting small car with fresh design and innovative technology for a lot of driving fun and a high level of quality. Specifically, OPEL sought to create a stylish yet warm interior to make it inviting. The new high-quality interior offers plenty of space, comfort, and opportunities for individualization. In addition, based on the popularity of the panorama sunroof that is an option for the 2005 Zafira compact van, OPEL wanted to offer a similar roof choice for the Corsa.

When OPEL designed the new Corsa, the company wanted to create a trend-setting small car with fresh design and innovative technology for a lot of driving fun and a high level of quality. Specifically, OPEL sought to create a stylish yet warm interior to make it inviting. The new high-quality interior offers plenty of space, comfort, and opportunities for individualization. In addition, based on the popularity of the panorama sunroof that is an option for the 2005 Zafira compact van, OPEL wanted to offer a similar roof choice for the Corsa.

Reader enquiries

GE PlasticsPlasticslaan 1

4600 AC Bergen op Zoom

Netherlands

Helen Vandebovenkamp

helen.vandebovenkamp@ge.com

Tel: +31 164 29 20 97

Fax: +31 164 29 10 66

Netherlands

Notes for editors

About GE Plastics

GE Plastics (www.geplastics.com) is a global supplier of plastic resins widely used in automotive, healthcare, consumer electronics, transportation, performance packaging, building & construction, telecommunications, and optical media applications. The company manufactures and compounds polycarbonate, ABS, SAN, ASA, PPE, PC/ABS, PBT and PEI resins, as well as the LNP* line of high-performance specialty compounds. GE Plastics, Specialty Film & Sheet manufactures high-performance Lexan* sheet and film products used in thousands of demanding applications worldwide. In addition, GE Plastics’ dedicated Automotive organization is an experienced, world-wide competitor, offering leading plastics solutions for five key automotive segments: body panels and glazing; under the hood applications; component; structures and interiors; and lighting. As a Worldwide Partner of the Olympic Games, GE is the exclusive provider of a wide range of innovative products and services that are integral to a successful Games.

* LNP and Lexan are trademarks of General Electric Company.

Editorial enquiries

Helen Vandebovenkamp

GE Plastics

Anne Clement

GE Plastics, Automotive

Tessa Vroegop

Marketing Solutions NV

Also available in